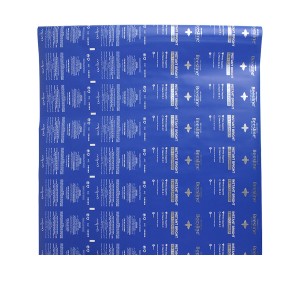

Custom Printed Film Roll Sachet Package Bags Rewind

What is Rewind Packaging

Rewind packaging refers to laminated film that’s put onto a roll. It is often used with form-fill-seal machinery (FFS). These machines can be used to shape the rewind packaging and to create sealed bags. The film is typically wound around a paperboard core (“cardboard” core, kraft core). Rewind packaging is commonly converted to single use “stick packs” or small bags for convenient on-the-go use for consumers. Examples include vital proteins collagen peptides stick packs, various fruit snack bags, single use dressing packets and crystal light.

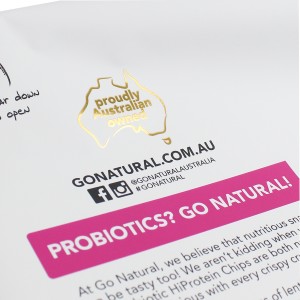

Whether you need rewind packaging for food, makeup, medical devices, pharmaceuticals or whatever else, we can assemble the highest quality rewind packaging that meets your needs. Rewind packaging occasionally gets a bad reputation, but that’s due to low quality film that is not being used for the correct application. While Dingli Pack is affordable, we never skimp on quality to undermine your manufacturing efficiencies.

Rewind packaging is often laminated as well. This will help protect your rewind packaging from water and gasses through the implementation of various barrier properties. Additionally, lamination can add an exceptional look and feel to your product.

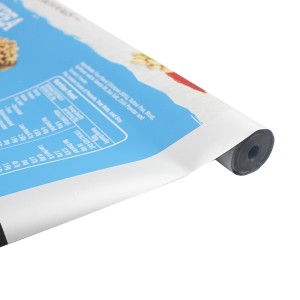

The specific materials used will depend on your industry and the exact application. Some materials work better for some applications. When it comes to food and certain other products, there are regulatory considerations as well. it is imperative to choose the right materials to be safe for food contact, readably machinability, and adequate for printing. There are multiple layers to stick pack films that give it unique properties and functionality.

These two-layer material packaging roll films have the following properties and functions: 1. PET/PE materials are suitable for vacuum packaging and modified atmosphere packaging of products, which can improve food freshness and extend shelf life; 2. OPP/CPP materials have good transparency and tear resistance, and are suitable for packaging of candy, biscuits, bread and other products; 3. Both PET/PE and OPP/CPP materials have good moisture-proof, oxygen-proof, fresh-keeping and corrosion-resistant properties, which can effectively protect the products inside the package; 4. The packaging film of these materials has good mechanical properties, can withstand certain stretching and tearing, and ensures the integrity and stability of the packaging; 5. PET/PE and OPP/CPP materials are environmentally friendly materials that meet food safety and hygiene requirements and will not pollute the products inside the package.

The three-layer structure of composite packaging roll film is similar to the two-layer structure, but it has an additional layer that provides extra protection.

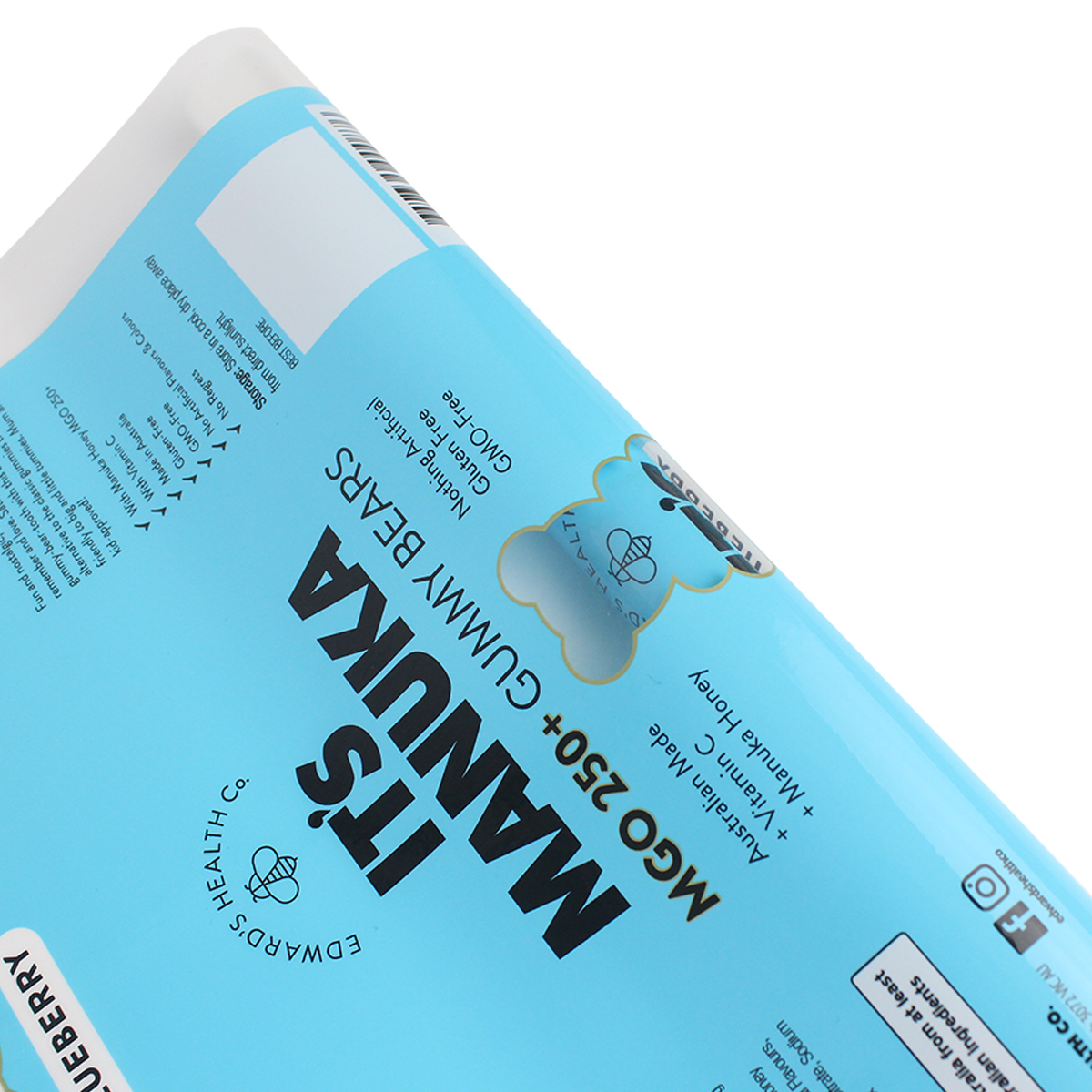

1. MOPP (biaxially oriented polypropylene film)/VMPET (vacuum aluminum coating film)/CPP (co-extruded polypropylene film): It has good oxygen resistance, moisture resistance, oil resistance and UV resistance, and has various forms. Bright film, matte film and other surface treatments. It is often used in the packaging of household daily necessities, cosmetics, food and other fields. Recommended thickness: 80μm-150μm.

2. PET (polyester)/AL (aluminum foil)/PE (polyethylene): It has excellent barrier and heat resistance, UV resistance and moisture resistance, and can also be used for anti-static and anti-corrosion. It is often used in packaging in the fields of medicine, food, engineering and electronic devices. Recommended thickness: 70μm-130μm.

3. The PA/AL/PE structure is a three-layer composite material consisting of polyamide film, aluminum foil and polyethylene film. Its features and capabilities include: 1. Barrier performance: It can effectively block external factors such as oxygen, water vapor, and taste, thereby protecting the quality of the product. 2. High temperature resistance: Aluminum foil has good thermal barrier properties, and can be used in microwave heating and other occasions. 3. Tear resistance: polyamide film can prevent the package from breaking, thus avoiding food leakage. 4. Printability: This material is very suitable for various printing methods. 5. Various forms: different bag-making forms and opening methods can be selected according to needs. The material is commonly used in packaging for food, medicine, cosmetics and agricultural products. It is recommended to use products with a thickness between 80μm-150μm.

Deliver,Shipping and Serving

By sea and express, also you can choose the shipping by your forwarder.It will take 5-7 days by express and 45-50 days by sea.

1. Is this material suitable for my product? Is it safe?

The materials we provide are food grade, and we can provide relevant SGS test reports. The factory has also passed the BRC and ISO quality system certification, meeting the safety standards for plastic packaging food.

2. If there is any problem with the quality of the bag, will you have good after-sales service? Will you help me redo it for free?

First of all, we need you to provide relevant photos or videos of bag quality problems so that we can track and trace the source of the problem. Once the quality problem caused by our company's production is verified, we will provide you with a satisfactory and reasonable solution.

3. Will you be responsible for my loss if the delivery is lost in the process of transportation?

We will cooperate with you to find the shipping company to discuss the compensation and the best solution.

4. After I confirm the design, what is the fastest production time?

For digital printing orders, the normal production time is 10-12 working days; for gravure printing orders, the normal production time is 20-25 working days. If there is a special order, you can also apply for expediting.

5. I still need to modify some parts of my design, can you have a designer to help me modify it?

Yes, we will assist you to finish the design for free.

6. Can you guarantee that my design will not be leaked?

Yes, your design will be protected and we will not disclose your design to any other person or company.

7. My product is a frozen product, will the bag be able to be frozen?

Our company can provide various functions of the bags, such as freezing, steaming, aerating, even packing corrosive objects are possible, you just need to inform our customer service before quoting the specific use.

8. I want recyclable or biodegradable material, can you do it?

Yes. We can produce recyclable material, PE/PE structure, or OPP/CPP structure. We can also do biodegradable materials such as Kraft paper/PLA, or PLA/Metalic PLA/PLA, etc.

9. What are the payment methods I can use? And what is the percentage of deposit and final payment?

We can generate a payment link on Alibaba platform, You can remit money by wire transfer, credit card, PayPal, and other means. The usual payment method is 30% deposit to start production and 70% final payment before shipment.

10. Can you give me the best discount?

Of course you can. Our quotation is very reasonable and we are looking forward to building a long term relationship with you.