Tsarin shirye-shiryen asali na jakunkuna marufi ya kasu kashi huɗu: bugu, laminating, slitting, yin jaka, waɗanda matakai biyu na laminating da yin jaka sune mahimman hanyoyin da ke shafar aikin samfur na ƙarshe.

Tsarin hadawa

Zane samfurin marufi tsari, ban da daidai zabi na daban-daban substrates, zabi na m adhesives kuma yana da muhimmanci, bisa ga yin amfani da kayayyakin, abun da ke ciki, post-sarrafa yanayi, ingancin bukatun ga ingancin zabi. Zaɓi manne da ba daidai ba, ko ta yaya cikakkiyar fasahar sarrafa kayan aikin, kuma za ta haifar da mummunan sakamako, da kuma bayan aiwatarwa don rage ƙarfin, ƙarƙashin ƙarfin haɗin gwiwa, ɗigogi, fashe jakunkuna da sauran gazawa.

Zaɓin marufi masu sassauƙa na yau da kullun tare da adhesives don yin la'akari da dalilai iri-iri, gabaɗaya, azaman manne mai haɗaɗɗiya yakamata ya dace da waɗannan sharuɗɗan.:

Mara guba

Babu ruwan 'ya'yan itace masu cutarwa da ke bayyana bayan tattara ruwa.

Ya dace da buƙatun zafin jiki na ajiyar abinci.

Kyakkyawan juriya na yanayi, babu rawaya da blister, babu alli da delamination.

juriya ga mai, dandano, vinegar da alcohols.

Babu lalacewa na tawada na bugu, ana tsammanin yana da kusancin tawada.

Bugu da ƙari, juriya ga yashwa, abun ciki ya ƙunshi babban adadin kayan yaji, alcohols, ruwa, sukari, fatty acid, da dai sauransu, kaddarorin su sun bambanta, yana iya yiwuwa ya shiga cikin ciki na fim ɗin da aka haɗa a cikin m Layer, yana haifar da lalacewar lalacewa, wanda ya haifar da delamination na jakar marufi, lalacewa ga gazawar. A sakamakon haka, manne dole ne ya sami ikon yin tsayayya da zaizayar abubuwan da ke sama, koyaushe yana kula da isasshen ƙarfin kwasfa.

Hanyoyin sarrafa fim ɗin filastik sune hanyar haɗaɗɗen bushewa, hanyar haɗaɗɗen rigar, hanyar haɗaɗɗen extrusion, hanyar narke mai zafi da hanyar haɗin haɗin gwiwa da sauran wasu da yawa..

1. Dry compounding

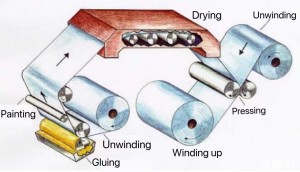

Hanyar lamination bushe ita ce hanyar da aka fi amfani da ita na lamination marufi. A karkashin wasu yanayi na zafin jiki, tashin hankali da kuma gudun, na farko substrate ne uniformly cika da Layer na sauran ƙarfi tushen m (daya-bangaren zafi narke m ko biyu-bangaren reactive m), bayan laminating inji yin burodi tashar (kasu kashi uku yankunan: evaporation zone, hardening yankin da kuma ware daga wari zone) sabõda haka, da zafi da latsa jihar da kuma rollers yankin, da kuma zafi latsa jihar rollers, da kuma zafi latsa jihar rollers. substrate na biyu (fim ɗin filastik, takarda ko foil na aluminum) wanda aka haɗa cikin fim ɗin da aka haɗa.

Dry lamination na iya laminate kowane nau'i na fim, kuma zai iya maye gurbin ikon haɗa kayan aiki mai mahimmanci bisa ga buƙatun manufar dangane da abubuwan da ke ciki. Sabili da haka, a cikin marufi, musamman a cikin marufi na yau da kullun an warware ci gaban.

2,Rigar hadawa

Rigar hadawa hanya ne mai hade substrate (fim filastik, aluminum tsare) mai rufi tare da Layer na m a kan surface, a cikin hali na m ba bushe, ta hanyar matsa lamba nadi da sauran kayan (takarda, cellophane) composite, sa'an nan kuma bushe bayan tanda a cikin wani hadadden fim.

Tsarin hadaddiyar rigar abu ne mai sauƙi, tare da ƙarancin mannewa, ƙarancin farashi, babban haɓakar haɗaɗɗen, da ware sauran sauran ƙarfi.

Wet composite laminating inji da kuma aiki ka'idar amfani da bushe composite Hanyar ne m guda, bambanci shi ne na farko substrate mai rufi da manne, na farko da na biyu substrate laminated composite, sa'an nan kuma bushe ta tanda. Sauƙaƙan, ƙarancin mannewa, saurin haɓakawa, samfuran haɗaɗɗiyar ba su ƙunshi sauran kaushi ba, madadin gurɓataccen yanayi.

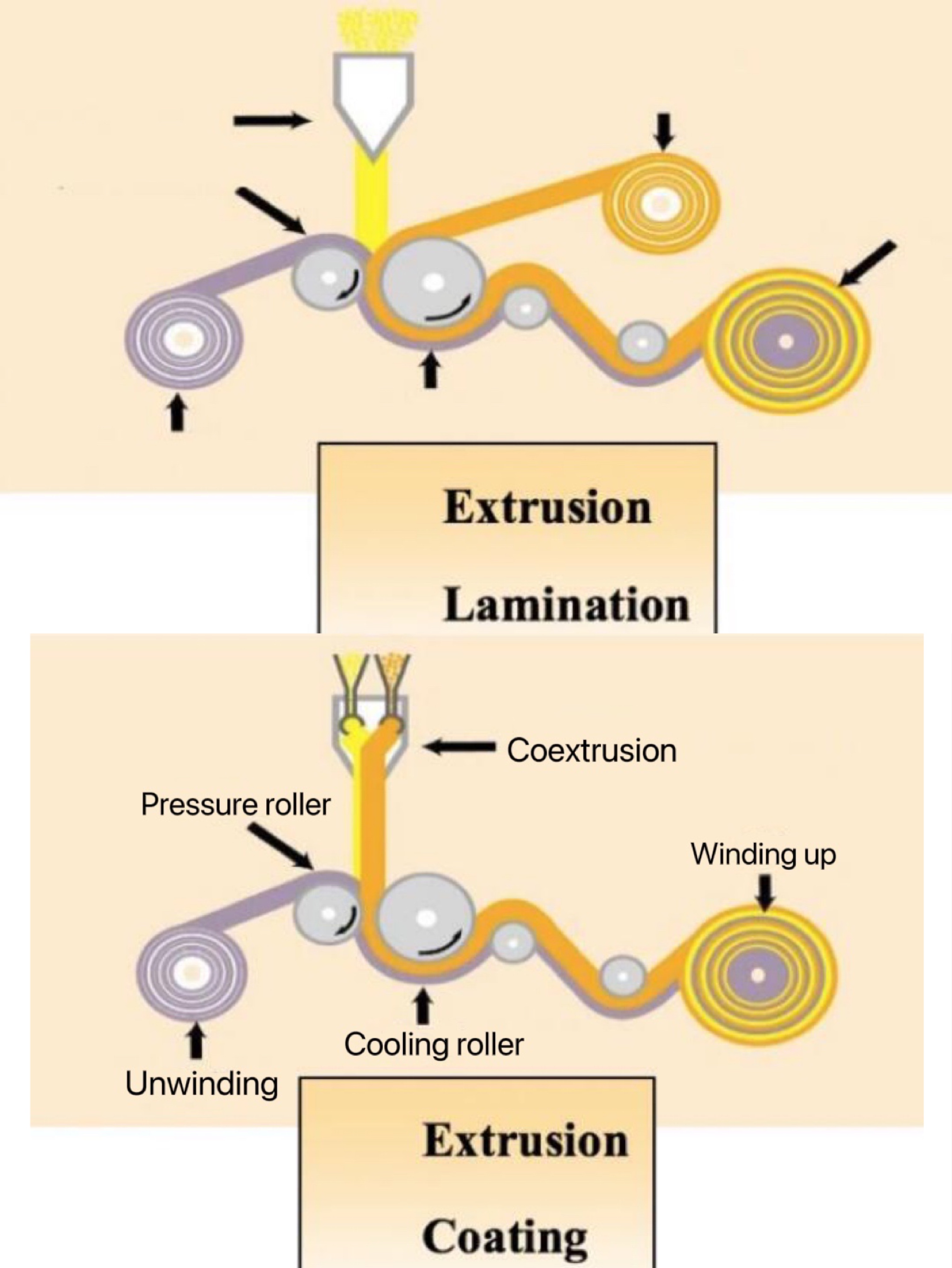

3. Extrusion hadaddun

Extrusion compounding shine mafi yawan hanyar da ake haɗawa, shine amfani da resin thermoplastic a matsayin ɗanyen abu, ana dumama resin a narke a cikin mold, da bakin mutuwa maimakon takardar maganin fim, nan da nan bayan an haɗa shi da wani nau'in fim ko biyu tare, sannan a sanyaya a warke. Multi-Layer co-extrusion lamination wani iri-iri daban-daban kaddarorin roba guduro ta fiye da extruder co-extrusion, a cikin mutu lamination a cikin fim.

Abubuwan da aka haɗa suna da haɗari ga matsalolin inganci da mafita

Compounding ne mai muhimmanci tsari a cikin samar da aiki na m marufi, da na kowa kasawa ne: samar da iska kumfa, low azumi zuwa compounding, ƙãre kayayyakin wrinkled da birgima gefuna, composite kayayyakin mikewa ko shrinkage, da dai sauransu.. Wannan sashe zai mayar da hankali a kan bincike na wrinkling, birgima gefuna na Sanadin da kuma hanyoyin da kawar.

1.Al'amarin wrinkle

A cikin bushewar hadaddiyar giyar wannan al'amari ya mamaye babban rabo na gazawar kai tsaye yana shafar ingancin jakan da aka gama.

Babban dalilan wannan gazawar sune kamar haka.

Mummunan ingancin hada kayan ko bugu da kanta, karkata a cikin kauri, film Rolls ne sako-sako da a duka iyakar da m a daya karshen saboda rashin daidaito iska tashin hankali. Idan girman fim ɗin ya rabu da elasticity na manyan, akan na'ura, fim ɗin sama da ƙasa da hagu da dama amplitude yana da girma sosai saboda lokacin da abu ya shiga tsakanin drum mai zafi da na'urar bugawa mai zafi, ba zai iya zama matakin tare da na'ura mai zafi mai zafi ba, don haka ba za a iya matse shi da lebur ba, wanda ya haifar da ƙãre hadaddun wrinkled, sakamakon layukan samfur. Lokacin da kayan haɗin kai shine PE ko CPP, idan kauri ya wuce 10μm, kuma yana da sauƙi don yaduwa, a wannan lokacin, za'a iya ƙara yawan tashin hankali na kayan haɗin gwiwar daidai, kuma matsi mai zafi na iya zama yanayin kwance don extrusion. Duk da haka, ya kamata a lura cewa tashin hankali ya kamata ya dace, tashin hankali mai yawa yana da sauƙi don sa kayan haɗin gwiwa ya yi tsawo, yana haifar da bakin jaka a ciki. Idan kauri karkata daga cikin hadaddun abu ne da girma, shi da gaske ba za a iya amfani da, ya kamata a magance.

2. Haɗaɗɗen fararen tabo

A sakamakon matalauta tawada ɗaukar hoto kudi fari spots: domin hada farin tawada, a lokacin da tawada sha volatilization amma ba volatilization lalacewa ta hanyar fararen spots, samuwa don inganta bushe iya aiki na hanya; idan har yanzu akwai fararen tawada, babban mafita shine a inganta ɗaukar hoto na farin tawada, kamar duba ingancin farin tawada, saboda niƙa mai kyau na ƙimar ɗaukar tawada mai ƙarfi yana da ƙarfi.

M maimakon unevenly samar farin spots: a cikin tawada Layer mai rufi da manne, saboda shigar da tawada zai sha da sauran ƙarfi, surface tashin hankali da kuma karami fiye da substrate, leveling dole ne ba da kyau kamar yadda haske fim mai rufi da manne, manne depressions da aluminum-plated surface ko aluminum tsare ba kusa Fit, nuna haske ta cikin kumfa lokacin da za su yi nuni da fari tabo, ko tabo. Ana iya amfani da maganin don sassaukar da rufin tare da abin nadi na roba iri ɗaya, ko ƙara yawan maye gurbin.

3. Kumfa mai yawa

Ana haifar da kumfa masu haɗaka a cikin yanayi masu zuwa da hanyoyin da suka dace.

Haɗin kumfa a cikin sabon abu

1. fim din mara kyau, ya kamata ya inganta ƙaddamar da mannewa da kuma adadin maye gurbin, MST, KPT surface ba sauki jika, sauki don samar da kumfa, musamman a cikin hunturu. Iska ta bubbuga tawada.iyayi amfani da hanyar ƙara yawan manne don cirewa.

2,Kumburin saman tawada da kumfa, yakamata a haɗa fim ɗin mahaɗar zafin jiki da matsa lamba don ƙarawa.

3, Adadin ƙara manne akan farfajiyar tawada yana da ƙasa, yakamata ya haɓaka lokacin matsi na abin nadi mai haɗawa da yin amfani da rollers masu santsi, preheating na fim ya isa ya rage saurin haɓakawa, zaɓi manne mai kyau wetting da daidai zaɓi na tawada.

4. Additives (mai lubricant, antistatic wakili) a cikin fim din suna shiga ta hanyar manne, don haka ya kamata ku zabi manne tare da nauyin kwayoyin halitta da sauri da sauri, ƙara yawan mannewa, tada zafin jiki na tanda don bushe manne sosai, kuma kada ku yi amfani da fim din tare da fiye da watanni 3 lokacin sanyawa, saboda maganin corona ya ɓace.

5,Yanayin zafin jiki a cikin hunturu yana da ƙasa, haɗin gwiwa zuwa fim ɗin da canja wurin tawada, sake saita tasirin daidaitawa ba shi da kyau, don haka wurin aiki yana kiyaye wani zafin jiki.

6,Yanayin bushewa ya yi yawa sosai, ƙumburi na manne ko ɓarkewar fata na faruwa, kuma ciki bai bushe ba, don haka ya kamata a daidaita yanayin bushewa na manne.

7. Ana shigar da iska a tsakanin fim din na'ura mai kwakwalwa, yawan zafin jiki na rollers ya kamata a kara yawan kuma ya kamata a lalata kusurwar haɗin gwiwa (fim ɗin yana da kauri da sauƙi don samar da kumfa lokacin da yake da wuya).

8,Saboda babban shingen fim, iskar CO2 da aka samar ta hanyar maganin mannewa, saura a cikin fim ɗin da aka haɗa, ba a buga shi a kumfa ba, ya kamata ya inganta adadin maganin warkewa, don haka maganin manne a bushe.

9. Glycolic acid da ke cikin roba yana da kyau ga mai cika tawada, roba yana narkar da tawada, kuma akwai kumfa kawai akan tawada, wanda yakamata ya guje wa shigar ruwa a cikin roba kuma ya inganta yanayin bushewa na roba don rage rushewar tawada.

4.Karfin kwasfa mara kyau

Ƙarfin kwasfa ba shi da kyau, saboda rashin cikakkiyar magani ne, ko kuma adadin manne ya yi kadan, ko tawada da aka yi amfani da shi da manne bai dace da yanayin ba, duk da cewa an kammala maganin, amma tsakanin nau'i biyu na fim ɗin da aka haɗe saboda rashin tsayi ya rage raguwar karfi.

Yawan allura na manne yana da ƙananan ƙananan, rabon manne yana raguwa, manne yana lalacewa a cikin ajiya, ruwa da barasa suna haɗuwa a cikin manne, abubuwan da suka dace a cikin fim din suna haɓakawa, bushewa ko tsarin balagagge ba a wurin ba, da dai sauransu, wanda zai haifar da sakamako na ƙarshe na rage ƙarfin kwasfa.

Kula da daidaitaccen ajiyar manne, mafi tsayi bai wuce shekara 1 ba (tila mai iya rufewa); hana abubuwan waje shiga cikin manne, musamman ruwa, barasa, da dai sauransu, wadanda ke haifar da gazawar gam. Fim ɗin da ya dace don inganta yawan adadin manne; inganta bushewa zafin jiki ƙarar iska, rage gudun hadawa. Jiyya na biyu na fuskar fim don inganta tashin hankali; rage amfani da Additives a cikin fim compounding surface. Duk waɗannan hanyoyin za su iya taimaka mana don inganta matsalar ƙarancin ƙarfin kwasfa na haɗuwa.

5. Hatimin zafi mara kyau

Jumhuriyar jakar zafi hatimi mummunan aiki da abubuwan sa sune ainihin yanayi masu zuwa.

Ƙarfin rufewar zafi ba shi da kyau. Babban dalilan da ke haifar da lamarin ba su cika warkewa ba ko zafin rufewar zafi ya yi ƙasa da ƙasa. Haɓaka tsarin warkarwa ko haɓaka yanayin zafin wuka daidai zai iya inganta matsalar.

Hatimin hatimin zafi delamination da fihirisar refractive. Babban dalilin wannan sabon abu shine haɗin gwiwa ba ya warkewa. Daidaita lokacin warkewa ko daidaita abun cikin wakili na iya inganta wannan matsalar.

Rashin buɗewa mara kyau / ƙarancin buɗewar fim ɗin Layer na ciki. Dalilin wannan al'amari shine ma'aikaci mai buɗewa kaɗan, wanda ke haifar da abu mai yawa (mai gyara) da kuma saman fim mai ɗanɗano ko mai mai. Ana iya inganta wannan matsala ta hanyar ƙara yawan adadin budewa, daidaita yawan adadin gyare-gyare, da kuma guje wa gurɓataccen abu na biyu a kan fuskar fim.

Karshen

Na gode da karatun ku, muna fatan za mu sami damar zama abokan hulɗarku.

Idan kuna da wata tambaya da kuke son yi, da fatan za ku ji daɗin sanar da mu kuma ku tuntuɓe mu.

Tuntuɓar:

Adireshin i-mel :fannie@toppackhk.com

WhatsApp : 0086 134 10678885

Lokacin aikawa: Afrilu-01-2022