Cov txheej txheem kev npaj ntawm cov hnab ntim khoom sib xyaw yog muab faib ua plaub kauj ruam: luam ntawv, laminating, slitting, hnab ua, uas ob txheej txheem ntawm laminating thiab lub hnab ua yog cov txheej txheem tseem ceeb uas cuam tshuam rau kev ua haujlwm ntawm cov khoom kawg.

Kev sib xyaw ua ke

Tsim cov txheej txheem ntim khoom, ntxiv rau qhov kev xaiv kom raug ntawm ntau yam substrates, kev xaiv ntawm cov nplaum nplaum kuj tseem ceeb heev, raws li kev siv cov khoom, muaj pes tsawg leeg, tom qab ua tiav, cov kev xav tau zoo rau kev xaiv zoo. Xaiv cov nplaum tsis raug, txawm tias qhov zoo tshaj plaws ntawm kev sib xyaw ua haujlwm zoo li cas, tseem yuav ua rau muaj qhov tshwm sim tsis zoo, nrog rau kev ua haujlwm tom qab kom txo tau cov quab yuam, nyob rau hauv kev sib xyaw quab yuam, to, tawg lub hnab thiab lwm yam tsis ua haujlwm.

Kev xaiv ntawm cov tshuaj niaj hnub hloov pauv ntim nrog cov nplaum los txiav txim siab ntau yam, feem ntau, raws li cov nplaum sib xyaw yuav tsum ua raws li cov hauv qab no.:

Tsis muaj tshuaj lom

Tsis muaj teeb meem rho tawm tshwm tom qab ntim cov kua.

Muaj feem xyuam rau qhov kub thiab txias ntawm kev cia khoom noj.

huab cua tsis zoo, tsis muaj yellowing thiab blistering, tsis muaj chalking thiab delamination.

tsis kam mus rau roj, flavors, vinegars thiab cawv.

Tsis muaj erosion ntawm printing qauv number case, xav kom muaj ib tug siab affinity rau number case.

Tsis tas li ntawd, kev tiv thaiv kev yaig, cov ntsiab lus muaj ntau cov txuj lom, cawv, dej, suab thaj, fatty acids, thiab lwm yam, lawv cov khoom sib txawv, nws muaj peev xwm nkag mus rau hauv txheej txheej ntawm cov zaj duab xis sib xyaw rau hauv cov nplaum nplaum, ua rau muaj kev puas tsuaj corrosion, ua rau delamination ntawm lub hnab ntim khoom, kev puas tsuaj rau cov khoom tsis ua haujlwm. Yog li ntawd, cov nplaum yuav tsum muaj peev xwm tiv taus qhov yaig ntawm cov khoom saum toj no, ib txwm tuav cov nplaum nplaum kom txaus.

Yas zaj duab xis composite txheej txheem yog qhuav composite method, ntub composite method, extrusion composite method, kub yaj composite method thiab co-extrusion composite method thiab ob peb lwm..

1, Qhuav compounding

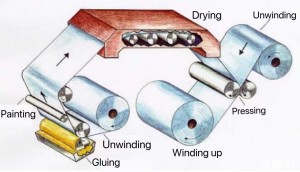

Dry lamination method yog txoj kev siv ntau tshaj plaws ntawm cov yas ntim lamination. Nyob rau hauv tej yam kev mob ntawm qhov kub thiab txias, nro thiab ceev, thawj substrate yog uniformly ntim nrog ib tug txheej ntawm hnyav-raws li nplaum nplaum (ib qho khoom kub yaj nplaum los yog ob lub ntsiab lus reactive adhesive), tom qab lub laminating tshuab ci channel (sib faib ua peb cheeb tsam: evaporation cheeb tsam, hardening cheeb tsam thiab cov exclusion ntawm cov ntxhiab tsw thiab evaporation cheeb tsam) xovxwm rollers, nyob rau hauv lub kub xovxwm lub xeev thiab lub thib ob substrate (yas zaj duab xis, daim ntawv los yog txhuas ntawv ci) bonded rau hauv ib tug composite zaj duab xis.

Qhuav lamination tuaj yeem laminate txhua yam ntawm zaj duab xis, thiab tuaj yeem hloov lub peev xwm los tsim cov khoom ntim khoom zoo raws li lub hom phiaj xav tau nyob ntawm cov ntsiab lus. Yog li ntawd, nyob rau hauv ntim, tshwj xeeb tshaj yog nyob rau hauv cov tshuaj niaj hnub ntim tau daws cov kev loj hlob.

2,Kev sib xyaw ntub dej

Cov txheej txheem ntub dej ntub dej yog cov txheej txheem sib xyaw ua ke (yas zaj duab xis, aluminium ntawv ci) coated nrog ib txheej ntawm cov nplaum rau ntawm qhov chaw, nyob rau hauv cov ntaub ntawv ntawm cov nplaum tsis qhuav, los ntawm lub siab cov menyuam thiab lwm yam ntaub ntawv (daim ntawv, cellophane) composite, thiab ces qhuav tom qab lub qhov cub rau hauv ib tug composite zaj duab xis.

Cov txheej txheem ntub dej sib xyaw yog qhov yooj yim, nrog cov nplaum nplaum tsawg, tus nqi qis, kev ua haujlwm siab zoo, thiab tsis suav cov kuab tshuaj seem.

Kev ntub dej sib xyaw lamination tshuab thiab cov qauv kev ua haujlwm siv thiab cov txheej txheem qhuav sib xyaw yog qhov zoo ib yam, qhov sib txawv yog thawj lub substrate coated nrog cov kua nplaum, ua ntej nrog lub thib ob substrate laminated composite, thiab tom qab ntawd qhuav los ntawm qhov cub. Yooj yim, tsis tshua muaj nplaum ntau npaum li cas, kev sib xyaw ua ke nrawm, cov khoom sib xyaw tsis muaj cov kuab tshuaj residual, kev ua qias tuaj rau ib puag ncig.

3, Extrusion compounding

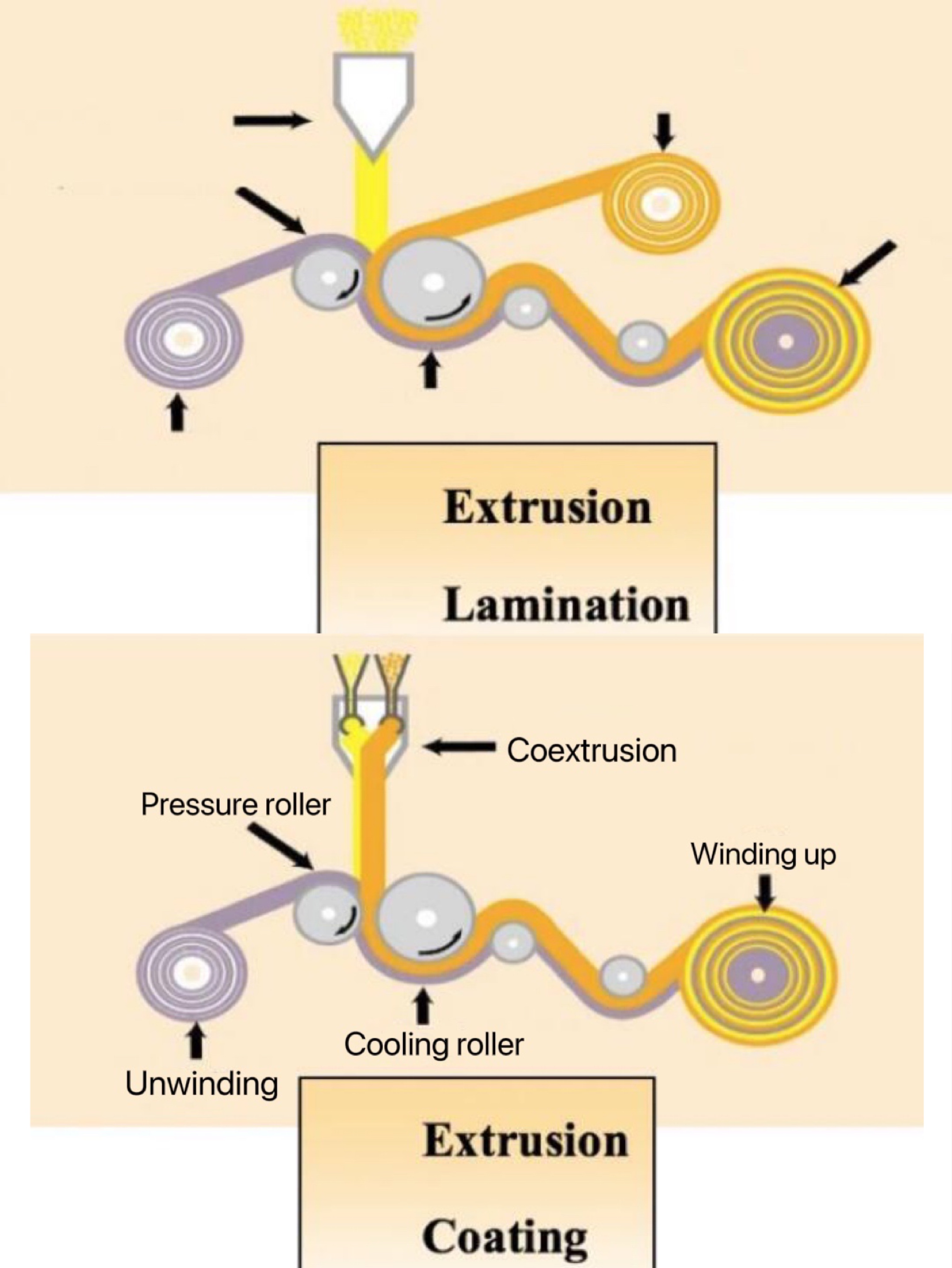

Extrusion compounding yog cov txheej txheem ntau tshaj plaws ntawm kev sib xyaw ua ke, nws yog kev siv cov thermoplastic cob ua raw khoom, cov resin yog rhuab thiab melted rau hauv pwm, los ntawm lub qhov ncauj tuag es tsis txhob ntawm daim ntawv curing ntawm zaj duab xis, tam sim ntawd tom qab compounding nrog lwm yam los yog ob films ua ke, thiab ces txias thiab kho. Multi-txheej co-extrusion lamination yog ntau yam khoom sib txawv ntawm cov yas resin los ntawm ntau tshaj rau extruder co-extrusion, mus rau hauv cov lamination tuag rau hauv zaj duab xis.

Cov ntaub ntawv sib xyaw ua ke yog qhov yooj yim rau cov teeb meem zoo thiab kev daws teeb meem

Compounding yog cov txheej txheem tseem ceeb hauv kev tsim khoom thiab kev ua tiav ntawm kev ntim khoom yooj yim, nws cov kev ua tsis tiav yog: kev tsim cov pa npuas, tsis tshua muaj nrawm rau kev sib xyaw, cov khoom tiav wrinkled thiab dov npoo, cov khoom sib xyaw stretch lossis shrinkage, thiab lwm yam. Qhov no yuav tsom rau kev tsom xam ntawm wrinkling, dov npoo ntawm qhov ua rau thiab cov txheej txheem ntawm kev tshem tawm.

1. Wrinkle phenomenon

Nyob rau hauv qhuav composite tsis ua hauj lwm ntawm qhov tshwm sim occupies ib tug loj feem ntawm qhov tsis ua hauj lwm ncaj qha cuam tshuam qhov zoo ntawm cov khoom tiav lub hnab-ua.

Cov laj thawj tseem ceeb rau qhov tsis ua haujlwm no yog cov hauv qab no.

Tsis zoo ntawm cov khoom siv sib xyaw lossis luam ntawv substrate nws tus kheej, sib txawv hauv cov tuab, zaj duab xis yob yog xoob ntawm ob qho tag nrho thiab nruj ntawm ib kawg vim qhov tsis sib npaug winding nro. Yog hais tias cov zaj duab xis ntim yog sib cais los ntawm elasticity ntawm lub loj, ntawm lub tshuab, cov zaj duab xis nce thiab nqis thiab sab laug thiab txoj cai qhov chaw amplitude kuj kuj loj vim hais tias thaum cov khoom nkag mus rau ntawm lub kub nruas thiab kub xovxwm rollers, nws yuav tsis tau theem nrog cov kub xovxwm rollers, yog li nws yuav tsis tau nyem tiaj tus, uas ua rau lub tiav composite wrinkled, oblique khoom kab. Thaum cov khoom sib xyaw yog PE lossis CPP, yog tias qhov sib txawv ntawm thickness yog ntau tshaj 10μm, nws kuj yog ib qho yooj yim rau wrinkle, nyob rau lub sij hawm no, qhov nro ntawm cov khoom sib xyaw tuaj yeem nce qhov tsim nyog, thiab kub nias rau cov menyuam tuaj yeem ua lub xeev kab rov tav rau extrusion. Txawm li cas los xij, nws yuav tsum tau muab sau tseg tias qhov nro yuav tsum tsim nyog, qhov nro ntau dhau yog yooj yim ua rau cov khoom sib xyaw elongated, ua rau lub hnab ntim lub qhov ncauj sab hauv qaij. Yog hais tias lub thickness sib txawv ntawm cov khoom sib xyaw yog loj heev, nws yeej siv tsis tau, yuav tsum tau ua nrog.

2 、 Cov pob dawb sib xyaw

Raws li qhov tshwm sim ntawm tus cwj pwm tsis zoo ntawm cov xim dawb: rau cov xim dawb sib xyaw, thaum tus number case absorption volatilization tab sis tsis volatilization tshwm sim los ntawm cov pob dawb, muaj los txhim kho lub peev xwm ziab ntawm txoj kev; Yog tias tseem muaj cov pob dawb, qhov kev daws teeb meem dav dav yog txhawm rau txhim kho cov xim xim dawb, xws li tshuaj xyuas qhov zoo ntawm cov xim dawb, vim tias qhov sib tsoo fineness ntawm tus number case zoo yog muaj zog.

Adhesive es tsis txhob ua tsis sib xws ntawm cov xim dawb: nyob rau hauv tus number case txheej coated nrog kua nplaum, vim nkag mus rau tus number case yuav nqus cov kuab tshuaj, nto nro thiab me dua substrate, leveling yuav tsum tsis zoo li lub teeb zaj duab xis coated nrog kua nplaum, kua nplaum depressions thiab aluminium-plated nto los yog txhuas ntawv ci tsis yog ib tug nyob ze haum, reflecting lub teeb los ntawm lub bubble los yog refractation. dawb paug. Cov kev daws teeb meem tuaj yeem siv los ua kom cov txheej txheem du nrog cov roj hmab cov menyuam tsis sib xws, lossis nce qhov hloov pauv.

3. Ua npuas ncauj

Cov npuas sib xyaw yog tsim nyob rau hauv cov xwm txheej hauv qab no thiab cov txheej txheem sib xws.

Cov npuas hauv qhov phenomenon

1. phem zaj duab xis, yuav tsum txhim kho cov concentration ntawm cov nplaum thiab cov nyiaj hloov, MST, KPT nto tsis yooj yim rau ntub, yooj yim los tsim npuas, tshwj xeeb tshaj yog nyob rau lub caij ntuj no. Cov huab cua npuas ntawm tus number case,ua tausiv txoj kev ua kom cov nplaum nplaum kom tshem tawm.

2,Tus number case nto pob thiab npuas, yuav tsum tau muab cov zaj duab xis compounding kub thiab compounding siab kom nce.

3, Tus nqi ntawm cov kua nplaum ntxiv rau ntawm tus number case yog tsawg, yuav tsum ua kom lub sij hawm sib xyaw ua ke ntawm cov menyuam siab muab tshuaj txhuam thiab siv cov rolls du, zaj duab xis preheating txaus kom txo tau cov compounding ceev, xaiv cov kua nplaum zoo thiab xaiv tus number case.

4. Cov additives (lubricant, antistatic agent) nyob rau hauv zaj duab xis yog nkag los ntawm cov kua nplaum, yog li koj yuav tsum xaiv cov kua nplaum uas muaj qhov hnyav molecular thiab ceev curing, ua kom cov kua nplaum ntau ntxiv, nce qhov kub ntawm qhov cub kom qhuav cov kua nplaum, thiab tsis txhob siv cov zaj duab xis nrog ntau tshaj 3 lub hlis kev tso kawm, vim tias kev kho corona tau ploj lawm.

5,Qhov kub ntawm lub caij ntuj no tsis tshua muaj, kev sib koom ua ke rau cov yeeb yaj kiab thiab cov cwj mem hloov pauv, rov pib ua kom zoo sib xws tsis zoo, yog li qhov chaw ua haujlwm khaws cia qee qhov kub.

6,Lub ziab kub yog siab dhau lawm, lub blistering ntawm cov nplaum los yog crusting ntawm daim tawv nqaij saum npoo tshwm sim, thiab sab hauv tsis qhuav, yog li qhov ziab ntawm cov nplaum yuav tsum tau kho.

7. Cov huab cua yog entrained ntawm lub composite rollers zaj duab xis, qhov kub ntawm cov khoom sib xyaw yuav tsum tau nce thiab lub kaum sab xis yuav tsum decomposed (cov zaj duab xis yog tuab thiab yooj yim los tsim npuas thaum nws nyuaj).

8,Vim tias muaj cov yeeb yaj kiab siab, cov roj CO2 ua los ntawm cov nplaum nplaum, cov seem hauv cov yeeb yaj kiab sib xyaw, tsis tau luam tawm ntawm cov npuas, yuav tsum txhim kho tus nqi ntawm tus neeg saib xyuas, kom cov nplaum ua kom qhuav.

9. Cov glycolic acid nyob rau hauv cov roj hmab yog cov kuab tshuaj zoo rau tus number case muab tub lim, cov roj hmab dissolves tus number case, thiab tsuas muaj npuas ntawm tus number case, uas yuav tsum tsis txhob muaj dej nkag mus rau hauv cov roj hmab thiab txhim kho qhov ziab ntawm cov roj hmab kom txo cov kua dej ntawm cov kua nplaum.

4 、 Lub zog tev tsis zoo

Peel lub zog tsis zoo, yog vim kev kho tsis tiav, lossis cov kua nplaum tsawg dhau, lossis cov kua nplaum siv thiab cov nplaum tsis haum rau qhov xwm txheej, txawm hais tias qhov kev kho tau tiav, tab sis ntawm ob txheej ntawm cov zaj duab xis sib xyaw vim qhov tsis muaj qhov ntev tau txo qis zog.

Qhov kev txhaj tshuaj ntawm cov kua nplaum yog me me, qhov sib piv ntawm cov nplaum yog txo, cov kua nplaum yog deteriorated nyob rau hauv cia, dej thiab cawv yog tov nyob rau hauv cov kua nplaum, cov auxiliaries nyob rau hauv cov zaj duab xis yog precipitated, lub qhuav los yog maturation txheej txheem tsis nyob rau hauv qhov chaw, thiab lwm yam, uas yuav ua rau lub kawg composite tev lub zog txo qhov tseem ceeb.

Ua tib zoo saib xyuas cov kua nplaum kom zoo, qhov ntev tshaj plaws yog tsis ntau tshaj 1 xyoos (tin tuaj yeem kaw tau); tiv thaiv cov khoom txawv teb chaws los ntawm kev nkag mus rau cov kua nplaum, tshwj xeeb tshaj yog dej, cawv, thiab lwm yam, uas tuaj yeem ua rau cov kua nplaum tsis ua haujlwm. Zaj duab xis tsim nyog los txhim kho cov kua nplaum txheej; txhim kho qhov ziab kom qhuav ntawm huab cua ntim, txo qhov ceev ntawm compounding. Kev kho thib ob ntawm zaj duab xis nto los txhim kho qhov nro; txo kev siv cov additives nyob rau hauv zaj duab xis compounding nto. Tag nrho cov txheej txheem no tuaj yeem pab peb txhim kho qhov teeb meem ntawm cov tawv nqaij tsis zoo ntawm cov khoom sib xyaw.

5. Thaum tshav kub kub foob tsis zoo

Compound hnab thaum tshav kub kub foob kev ua haujlwm tsis zoo thiab nws cov laj thawj yog cov xwm txheej hauv qab no.

Thaum tshav kub kub sealing lub zog tsis zoo. Lub ntsiab yog vim li cas rau qhov tshwm sim tsis kho kom zoo los yog kub sealing kub yog tsawg heev. Txhim kho cov txheej txheem kho kom zoo lossis tsim nyog ua kom qhov kub hnyiab tau tuaj yeem txhim kho qhov teeb meem.

Thaum tshav kub kub foob npog delamination thiab refractive index. Qhov laj thawj tseem ceeb ntawm qhov tshwm sim no yog kev sib txuas lus tsis kho. Kho lub sij hawm kho los yog kho cov ntsiab lus kho tus neeg sawv cev tuaj yeem txhim kho qhov teeb meem no.

Kev qhib tsis zoo / kev qhib tsis zoo ntawm cov yeeb yaj kiab sab hauv. Qhov ua rau ntawm qhov tshwm sim no yog qhib tus neeg sawv cev tsawg dhau, ua rau cov khoom siv ntau dhau (modifier) thiab nplaum los yog greasy zaj duab xis nto. Qhov teeb meem no tuaj yeem txhim kho los ntawm kev nce tus nqi ntawm tus neeg sawv cev qhib, kho tus nqi ntawm kev hloov kho, thiab tsis txhob muaj cov kab mob sib kis ntawm cov yeeb yaj kiab.

Qhov Kawg

Ua tsaug rau koj nyeem, peb vam tias peb muaj lub sijhawm los ua koj tus khub.

Yog tias koj muaj lus nug xav nug, thov koj xav tiv tauj peb thiab tiv tauj peb.

Hu rau:

E-mail chaw nyob:fannie@toppackhk.com

Whatsapp: 0086 134 10678885

Post lub sij hawm: Apr-01-2022