Have you ever wondered why packaging plays such a significant role in your shipping expenses? It might surprise you that the design of your stand-up pouch could be the key to cutting those costs. From the materials you choose to the size and shape, every detail of your packaging influences how much you’ll pay to get your products from factory to customer. In this post, we’ll explore how smart stand-up pouch design can help minimize transportation costs without compromising quality or protection.

Choosing the Right Materials for Efficient Stand-Up Pouch Packaging

The first step to reducing transportation costs starts with material selection. Flexible, lightweight materials like polyethylene and polypropylene are often the go-to choices for stand-up pouches. These materials provide excellent durability without adding excessive weight, which directly affects shipping rates. Additionally, thinner films with barrier properties, such as oxygen and moisture resistance, ensure your product stays fresh while reducing the weight and bulk of the packaging.

A well-designed pouch bag not only saves on material costs but also enhances the customer experience. Eco-friendly materials like compostable or recyclable films are becoming more popular, not only for their environmental impact but also for their ability to reduce packaging weight. Ultimately, the right materials ensure that your product is protected, your transportation costs are minimized, and your brand appeals to eco-conscious consumers.

Optimizing Stand-Up Pouch Dimensions for Cost Savings

Size matters when it comes to transportation efficiency. Oversized or bulky packaging can take up more space in shipping containers, resulting in higher freight costs. Optimizing your stand-up pouch dimensions to match the exact volume of your product can significantly cut down shipping expenses.

Consider the “nesting” effect: by ensuring your stand-up pouches can be packed efficiently, you maximize the use of space in pallets and boxes. This also applies to choosing the right pouch shapes—tapered or square-bottom designs allow for better stacking, reducing unused space and making transportation more efficient.

The Role of Sealing and Durability in Transportation Efficiency

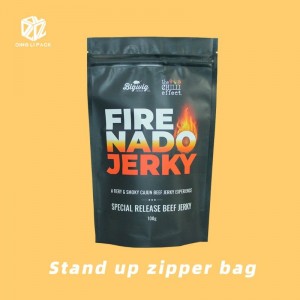

A properly sealed and durable stand-up pouch protects your product during shipping, preventing damage and reducing waste. Strong heat seals or resealable zippers ensure that your pouches remain intact throughout the supply chain. Durable materials that withstand temperature changes, punctures, and pressure also minimize the risk of product loss or damage, which would otherwise add to your overall costs.

Stand-up pouches are especially effective at protecting products like food, cosmetics, or small parts, which may be sensitive to handling. By keeping the product secure, you avoid additional expenses related to returns, replacements, and customer dissatisfaction.

How Stand-Up Pouches Reduce Storage and Freight Costs

One often-overlooked benefit of stand-up pouches is their ability to save on both storage and freight costs. Flexible pouches can be compressed or flattened when empty, allowing you to store a large volume of packaging materials in a small space. This also reduces your warehouse costs. When filled, stand-up pouches take up less room than rigid packaging, enabling you to ship more products in fewer shipments.

Because stand-up pouches are lightweight, they can lower your overall shipping weight—an important factor if you're working with international shipping rates, where every gram matters. This efficiency not only reduces direct costs but also shortens lead times, getting your products to market faster.

Customization for Specific Industries: A Tailored Approach to Cost Reduction

Each industry has unique packaging needs. Whether you’re packaging food, pharmaceuticals, or electronics, custom stand-up pouches can be tailored to reduce waste and streamline transportation. For example, food-grade stand-up pouches with high-barrier films ensure freshness without requiring bulky secondary packaging.

For companies shipping internationally, resealable or tamper-evident closures can minimize the need for extra security packaging, reducing both material costs and shipping weight. Customizing your stand-up pouches for your specific industry helps you cut costs while ensuring the quality and integrity of your product.

Why Partnering with the Right Manufacturer Matters

No matter how well-designed your stand-up pouch is, if your manufacturer isn’t capable of producing high-quality packaging at scale, your efforts to minimize costs will fall short. Look for a packaging manufacturer with extensive experience, cutting-edge technology, and a commitment to quality control. The right partner will offer you cost-effective solutions, from material selection to packaging design, while ensuring that your packaging is produced on time and within budget.

At Huizhou Dingli Pack, we pride ourselves on providing custom stand-up pouch solutions that not only meet industry standards but also help our clients save on shipping and storage costs. With our advanced printing technology, eco-friendly materials, and tailored designs, we help businesses across industries achieve the perfect balance between cost and quality.

Conclusion: Designing Smart Packaging to Boost Your Business

Reducing transportation costs doesn’t mean sacrificing quality or customer satisfaction. By choosing the right materials, optimizing your stand-up pouch dimensions, and partnering with an experienced manufacturer, you can streamline your logistics while delivering top-quality products. Smart packaging design is the key to reducing costs, increasing efficiency, and growing your business.

Post time: Sep-02-2024