We Xindingli Pack have been offering one-stop packaging customization service for over ten years. Our track record speaks for itself, as we have provided perfect packaging bag design solutions for numerous brands. In the upcoming article, we are thrilled to share one of our most recent and successful case studies. Join us as we delve into the details of this standout project, getting to know how our creative expertise resulted in such highly successful packaging solutions.

Packaging Inspiration from Our Customers’ Request

Our clients have expressed great satisfaction with our foregoing child-resistant cannabis packaging bags, and now they plan to expand their services to include a matching series of prerolls boxes. Then we’re asked to design new series of child-resistant prerolls boxes. After a month of communication and negotiation, we have jointly created this perfect packaging design. Next, Join us to delve into the creative process and the vision behind the development of these new packaging solutions, aimed at providing both functionality and aesthetic appeal.

As is known to us all, storing prerolls properly is essential to maintaining their flavor, aroma, and overall quality. Proper measure to store prerolls products is to keep them in a suitable environment, such as a humidor or a cool and dry place. Furthermore, suitable packaging also helps preserve these high-quality prerolls and even contributes to a more pleasurable smoking experience.

Based on the combination of customer requirements and the storage conditions of prerolls products, Let’s get started to customize exclusive child-resistant packaging:

Our Customer’s Requirements for Packaging Design:

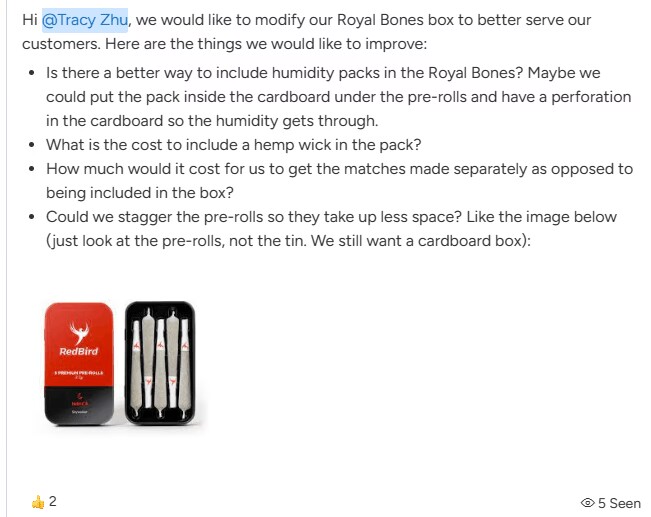

They would like to modify their previous Royal Bones box to better serve their target customers. Here are some factors they suggested to improve:

1. If they could put the pack inside the cardboard under the prerolls and have a perforation in the cardboard so the humidity gets through.

2. If they could stagger the prerolls so they take up less space.

Step One: Unleash Our Creativity

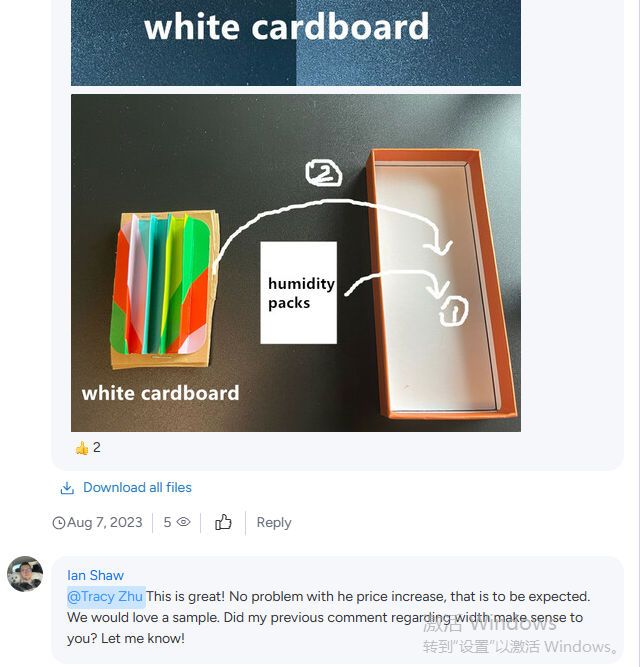

Reviewing our customers’ design requirements: this packaging material must be cardboard; this packaging must have holes to make humidity spread out; and its internal structure is compact enough. Our team folded out a preliminary model of this packaging box with paper (as can be seen from the picture).

The whole packaging box is divided into two parts: external box structure, internal folding storage structure, in which the gap between the internal structure has small holes to make moisture get out. These elements basically constitute the prototype design of this packaging. Then we sent this model to our customers and they were very satisfied with it.

Step Two: Recreate Original Design

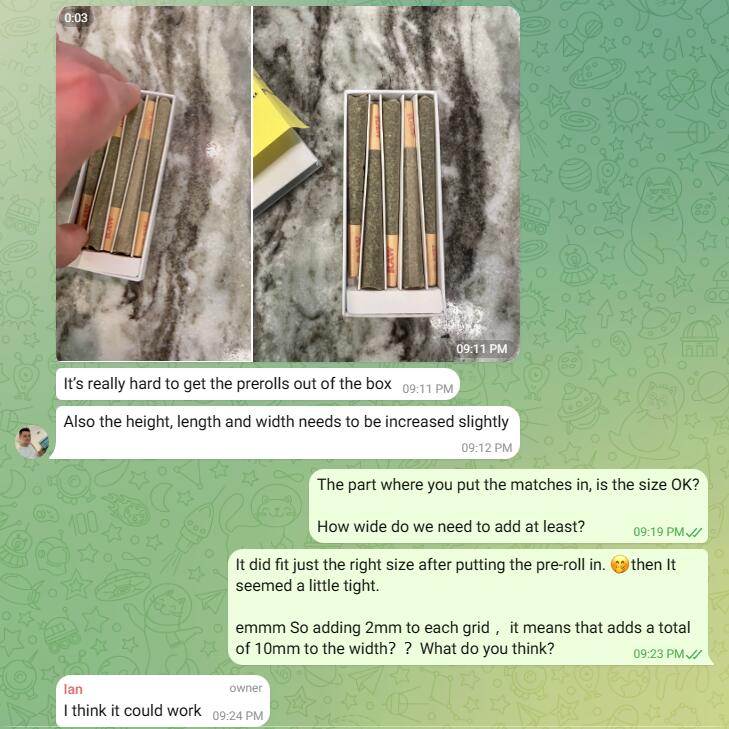

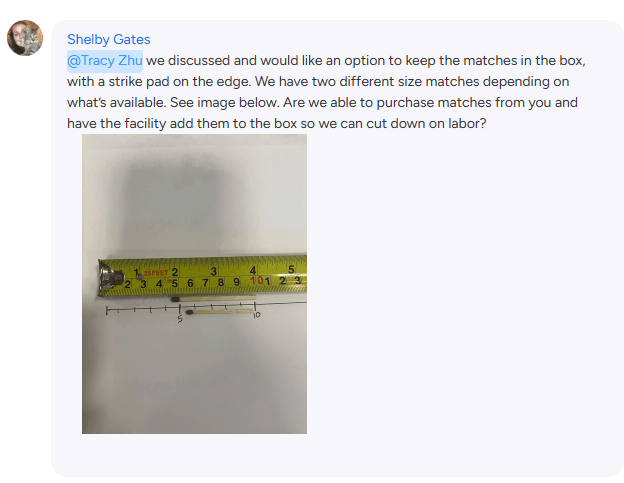

After a few days our customers made new demands: They would like an option to keep the matches in the box, with a strike pad on the edge. Then we started a new round of ideas on this packaging boxes. Here comes new packaging solution: We reserved a portion of space in the internal box structure for those two types of matches. Match storage space is made of sealed structure with strike pad on the edge, which forms two relatively independent space compared with prerolls storage space.

Step Three: Modify Packaging Sizes

After we sent our sample packs to our customers for testing, they reflected: It’s hard to get the inside prerolls products out of the box. And they suggested that the height, length, and width of box needs to be increased slightly. Then our team come up a now ideal: Adding 2mm more to each grid, that is to say, adding a total of 10mm to the width. After several rounds of communication, the design of child-resistant prerolls packaging boxes are finally completed perfectly.

![VGP1]RN$18GS7(TZMJ`_(`G](https://www.toppackcn.com/uploads/VGP1RN18GS7TZMJ_G.png)

Post time: Jan-05-2024