In the world of custom packaging, particularly for custom stand-up pouches, one of the biggest challenges that manufacturers face is ink smearing during the lamination process. Ink smearing, also known as "dragging ink," not only ruins the appearance of your product but can also result in unnecessary delays and higher production costs. As a trusted stand-up pouches manufacturer, we understand the importance of delivering high-quality, flawless packaging solutions, which is why we have developed expert methods to prevent ink smearing and ensure perfect results every time.

Let’s take a closer look at the steps we take to eliminate this issue, ensuring our custom-printed stand-up pouches are always up to the highest standards.

1. Precise Adhesive Application Control

The key to avoiding ink smearing begins with controlling the amount of adhesive used in the lamination process. Using too much adhesive can mix with the printed ink, causing it to smudge or smear. To solve this, we carefully choose the right adhesive type and adjust the application levels to ensure optimal adhesion without excess. For single-component adhesives, we maintain a working concentration of around 40%, and for two-component adhesives, we aim for 25%-30%. This careful control of adhesive quantity minimizes the risk of ink transfer onto the laminate, keeping the print clean and sharp.

2. Fine-Tuning Glue Roller Pressure

The pressure applied by the glue rollers is another critical factor in preventing ink smearing. Too much pressure can push the adhesive too far into the printed ink, leading to smudging. We adjust the glue roller pressure to ensure just the right amount of pressure is applied—enough to bond the layers effectively without affecting the print. Additionally, if any ink smearing is noticed during production, we use a diluent to clean the rollers, and in more serious cases, we stop the production line for a complete cleaning. This attention to detail ensures that the final product is free from any ink defects.

3. High-Quality Glue Rollers for Smooth Application

To further reduce the risk of ink smearing, we use premium-quality glue rollers with smooth surfaces. Rough or damaged rollers can transfer excess adhesive onto the print, leading to smearing. We ensure that our glue rollers are regularly maintained and have the best quality possible to avoid these issues. This investment in high-quality rollers ensures that every pouch receives a perfect application of adhesive, resulting in a clear and vibrant print every time.

4. Perfectly Matched Machine Speed and Drying Temperature

Another common cause of ink smearing is mismatched machine speed and drying temperature. If the machine runs too slowly or the drying temperature is too low, the ink doesn’t bond properly to the material before the laminate is applied. To address this, we fine-tune both the machine speed and the drying temperature, making sure they are perfectly synchronized. This ensures that the ink layer dries quickly and securely, preventing any smearing when the adhesive is applied.

5. Compatible Inks and Substrates

Choosing the right ink and substrate combination is critical for preventing smearing. We always ensure that the inks used in our custom-printed stand-up pouches are compatible with the materials being used. If the ink doesn’t adhere well to the substrate, it can smear during the lamination process. By using inks that are specifically designed for the substrates we work with, we ensure that the print stays sharp, vibrant, and free from smears.

6. Regular Equipment Maintenance

Finally, regular maintenance and inspection of the mechanical components of the printing and lamination equipment are essential. Worn or damaged gears, rollers, or other parts can cause misalignment or uneven pressure, resulting in ink smearing. We conduct routine checks and maintenance on all our machinery to ensure that every component is working in perfect sync. This proactive approach helps avoid issues during production, ensuring that our custom stand-up pouches maintain their high quality.

Conclusion

As a leading stand-up pouches manufacturer, we are committed to producing custom-printed stand-up pouches that not only meet but exceed our clients' expectations. By carefully controlling adhesive application, adjusting roller pressure, maintaining top-quality equipment, and selecting the right materials, we prevent ink smearing from affecting the quality of our products. These meticulous steps allow us to deliver packaging that is as flawless as it is functional.

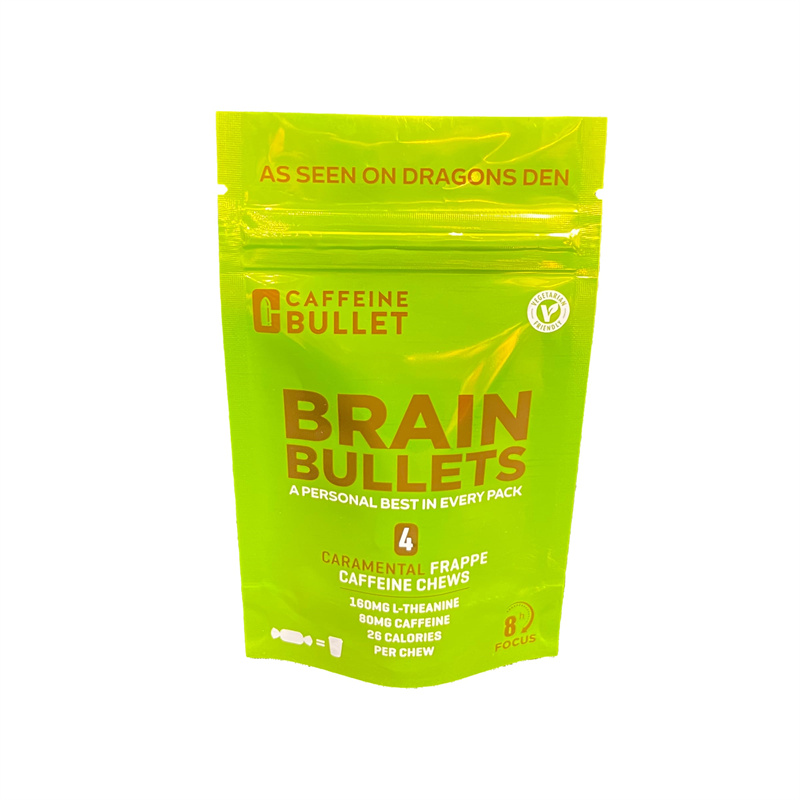

If you're looking for reliable, high-quality packaging solutions, look no further. Our Custom Glossy Stand-Up Barrier Pouches with laminated plastic doypacks and resealable zippers are designed to preserve your products' freshness while presenting your brand in the best light. Get in touch with us today to discuss how we can provide tailored packaging solutions for your business!

Post time: Nov-28-2024