In the ever-evolving world of flexible packaging, the stand up zipper pouch has risen as a favored choice for brands aiming to blend convenience, functionality, and visual appeal. But with countless products vying for consumer attention, how can your packaging truly stand out? The answer lies in UV Printing—a cutting-edge printing technique that combines vibrant colors, tactile finishes, and unmatched durability. Whether you’re packaging gourmet snacks, pet food, or cosmetics, UV printing transforms ordinary pouches into extraordinary marketing tools.

The Science Behind UV Printing

According to industry statistics, the global UV inkjet printing market is worth $5.994 billion in 2023 and is expected to grow to $8.104 billion in 2024, with a compound annual growth rate of 10.32%, reflecting a steady rise in printing demand. UV Printing stands out due to its innovative use of ultraviolet light to cure inks instantly. This technology results in superior print quality, glossy finishes, and durability that traditional printing methods simply cannot match.

Core Components of UV Ink:

1.Oligomers and Monomers: The building blocks of UV ink, controlling flexibility and ink viscosity.

2.Photoinitiators: Essential for triggering the curing process, these components ensure rapid drying under UV light.

3.Pigments: Deliver bold and vivid colors, essential for impactful branding.

How the Curing Process Works:

UV ink cures through a photochemical reaction triggered by high-powered ultraviolet light. This instant drying process eliminates the need for additional drying time and is ideal for a variety of substrates, including the plastic films commonly used in stand up zipper pouches.

Why UV Printing Is Perfect for Stand Up Pouches

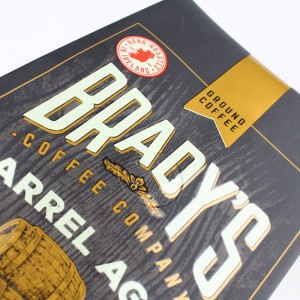

1. A Premium Look That Commands Attention

UV printing enhances the appeal of custom stand-up pouches by offering high-gloss finishes, vibrant colors, and unique tactile effects. With options like UV spot printing, brands can accentuate logos, patterns, or other design elements, adding a luxurious touch to their packaging.

2. Unmatched Durability

Packaging endures significant wear and tear during transportation and storage. UV printing creates robust, smudge-resistant, and fade-resistant designs, ensuring your branding remains impeccable from production to the end consumer.

3. Adaptability Across Materials

Whether your pouches feature a matte finish, transparent window, or metallic sheen, UV printing adapts seamlessly. This versatility makes it a go-to choice for stand up pouch factories aiming to meet diverse client needs.

Advantages and Challenges of UV Printing

Advantages:

Speed: Instant curing allows for faster production times, reducing delays even for bulk orders.

Eco-Friendly: With zero VOC emissions, UV printing is a sustainable choice that aligns with modern environmental standards.

Enhanced Design Capabilities: From bold colors to intricate details, UV printing creates designs that captivate consumers.

Wide Compatibility: UV printing is effective on various substrates, from plastics to metalized films.

Challenges:

Higher Costs: UV printing equipment and inks involve higher initial investments compared to traditional methods.

Specialized Expertise: Operating UV printers requires skilled technicians to ensure consistent quality.

Surface Preparation: The surface of the material must be prepped appropriately to achieve optimal adhesion.

Elevating Packaging with UV Spot Printing

Imagine a Custom UV Spot 8-Side Seal Flat Bottom Bag that combines striking aesthetics with functional features:

Front and Back Panels: Enhanced with UV spot printing for a bold, tactile effect that highlights key branding elements.

Side Panels: One side features a clear window for product visibility, while the other showcases intricate, customizable designs.

Eight-Side Seal: Offers maximum freshness and protection, perfect for food, pet products, or premium goods.

This combination of design and functionality ensures your stand-up pouches stand out on retail shelves while protecting their contents.

Why Choose Us

At DINGLI PACK, we specialize in creating custom printed stand-up pouches equipped with advanced UV printing technology. Our team of experts ensures every detail, from design to execution, reflects your brand’s vision.

What We Provide:

Custom UV Spot Printing: Highlight your brand with luxurious finishes.

Flexible Design Options: Choose from transparent windows, metallic effects, or matte finishes.

High-Volume Capability: Efficient production lines handle bulk orders with fast turnarounds.

Whether you’re a food brand, beauty business, or pet product company, our packaging solutions are tailored to meet your needs and exceed your expectations.

FAQs About UV Printing and Stand-Up Pouches

What is UV spot printing, and how does it enhance pouches?

UV spot printing highlights specific areas of a design, adding a glossy, tactile element that draws consumer attention.

Are UV-printed pouches durable enough for long-term storage?

Yes, UV printing provides exceptional durability, protecting designs from smudging, fading, and scratching.

Can UV printing be applied to eco-friendly materials?

Absolutely. UV printing works on a variety of sustainable substrates, including recyclable and compostable films.

What customization options are available for stand-up pouches with UV printing?

Options include transparent panels, metallic finishes, matte or glossy textures, and full-color designs tailored to your brand.

Is UV printing cost-effective for small businesses?

While initial costs are higher, the durability and visual appeal of UV printing often result in better ROI through increased customer engagement.

Post time: Dec-11-2024