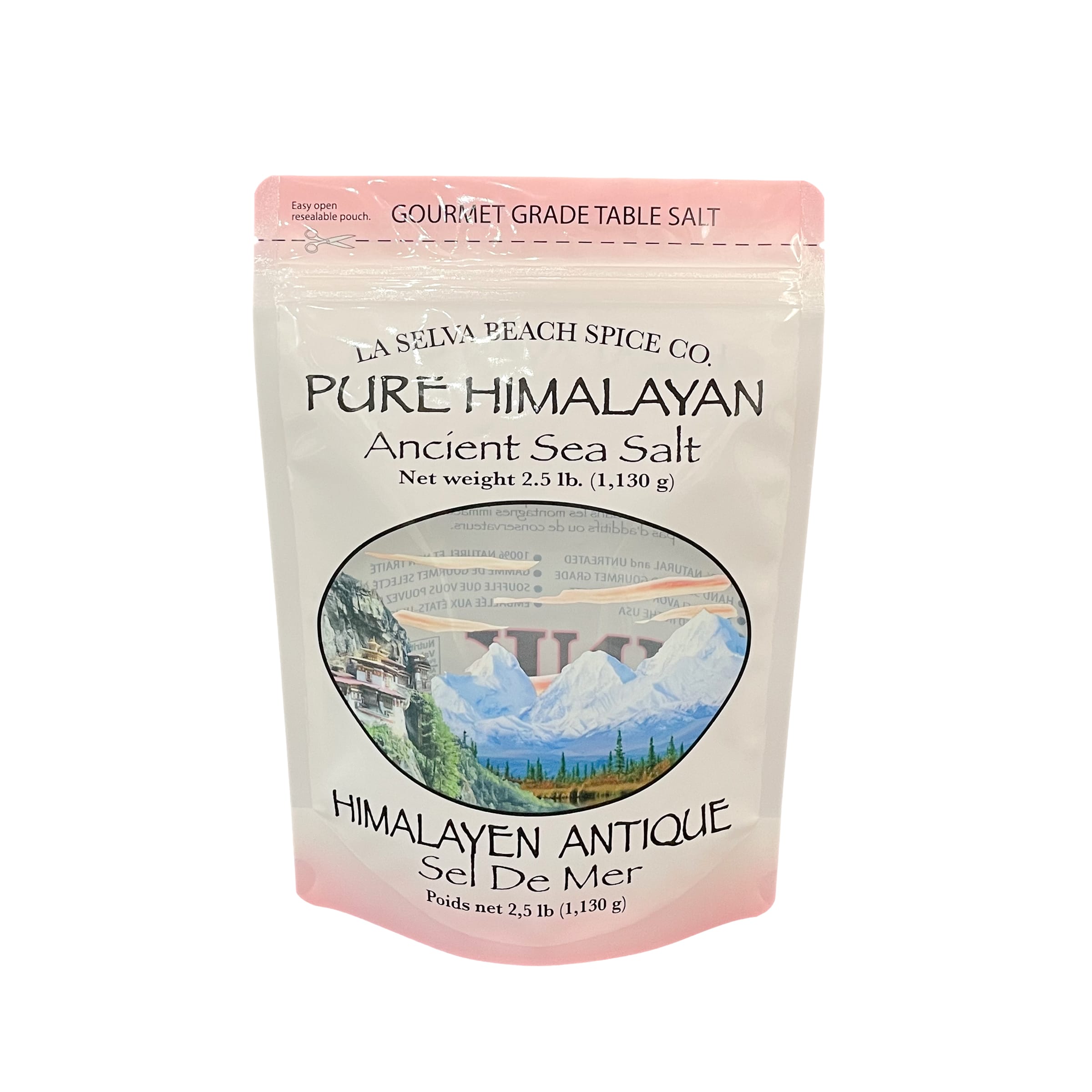

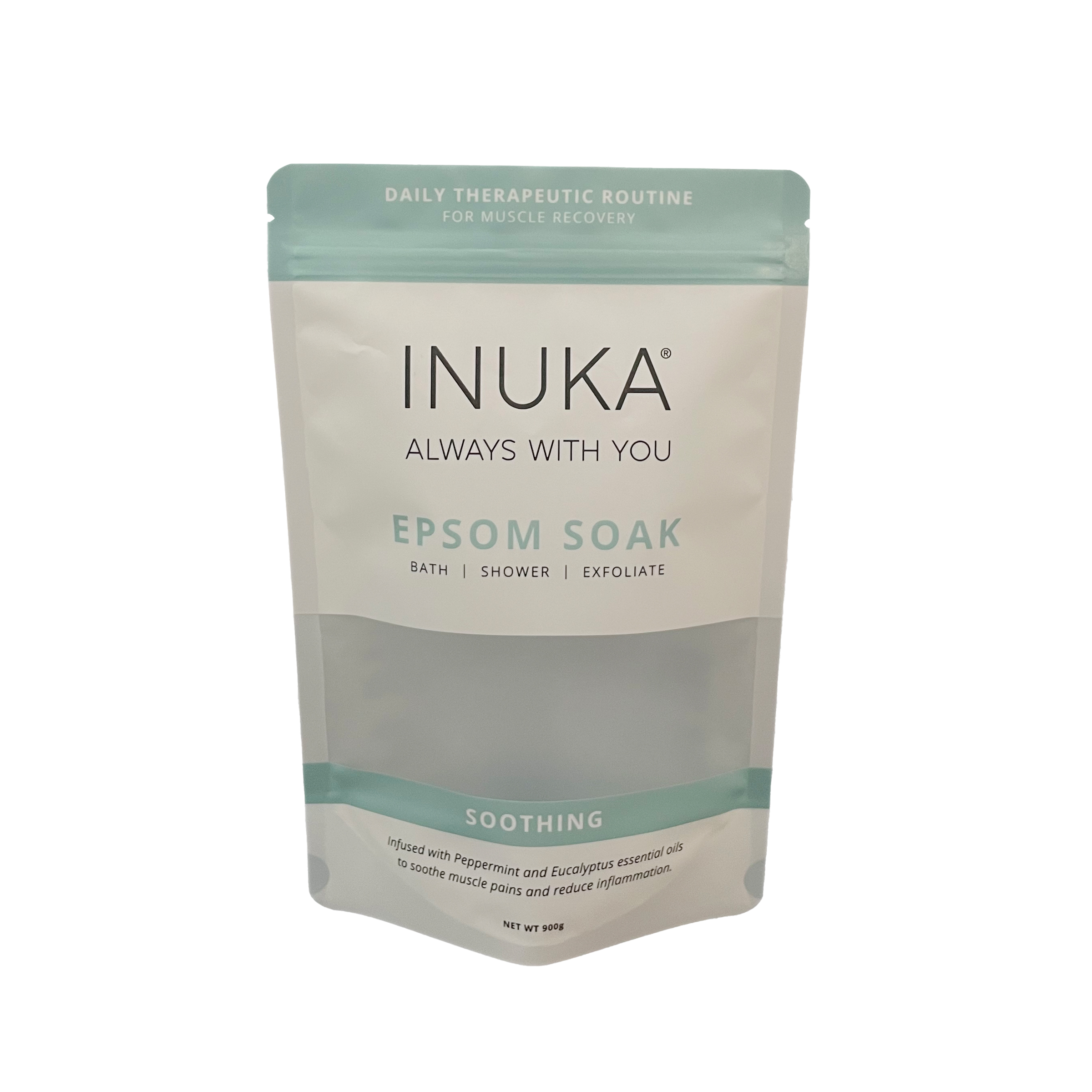

Are you ready to elevate your packaging game? Resealable bags for packaging offer a convenient solution that not only protects your products but also enhances their visual appeal. When it comes to modern packaging, custom stand up pouches with zippers are leading the charge. Let’s explore the essential components of producing high-quality custom stand up pouch bags that resonate with your needs.

The Right Materials Make All the Difference

Selecting the best materials is the foundation of any successful custom printed stand up pouch. For the outer layer, opt for materials that offer heat resistance and minimal thermal deformation, such as BOPP, PET, NY or Kraft paper. The inner layer should be a heat-sealable material with a melting point at least 30°C lower than the outer layer, ideally thicker than 30μm.

When choosing zippers, ensure that the sealing strip has a lower heat sealing temperature—about 5-10°C below the inner layer—to achieve a secure closure without compromising the integrity of your packaging.

Prepare for Success Before Production

Preparation is key to producing high-quality stand up pouch bags. Ensure that the composite film layers are fully cured to prevent distortion during the sealing process. Select an appropriate sealing surface and keep it clean to ensure a smooth operation. It’s also critical to check the heat-resistant cloth for any defects before beginning production.

Set the sealing temperature in advance and allow it to preheat for at least 20 minutes. This ensures consistent quality throughout your production run, leading to reliable results every time.

Heat Sealing Temperature: Getting It Just Right

Establishing the correct heat sealing temperature is vital for the success of your custom stand up pouches. The temperature must be tailored to the materials used, their thickness, and the production speed. Generally, the sealing temperature should exceed the melting point of the heat-sealable material to ensure strong seals.

Remember, if the temperature is too low, the seals may fail. Conversely, excessive heat can damage the material, compromising the strength of the seal. Finding that sweet spot is essential for creating durable packaging.

Sealing Pressure: Balancing Act for Quality

Proper sealing pressure is crucial for producing strong, effective seals on your stand up pouches. Aim for a pressure of about 3mm at the sealing knife edge, ensuring it is balanced on both sides. If the pressure is insufficient, the seals will be weak. Too much pressure, however, can thin the material, reducing overall strength.

Timing Matters: Sealing Duration and Cooling

The duration of the heat sealing process affects the quality of the seal. A longer sealing time allows for better fusion of the layers but be cautious—excessive time can lead to shrinkage, impacting the pouch's appearance.

After sealing, cooling is equally important. Make sure the cooling temperature is appropriate to prevent condensation on the sealing knife. Adequate cooling helps maintain both seal strength and visual quality.

Sealing Multiple Times for Maximum Strength

For optimal sealing strength, it’s advisable to repeat the sealing process at least twice. The number of vertical seals required is determined by the effective length of the sealing knife in relation to the pouch length, while horizontal sealing depends on the number of horizontal sealing devices available in the pouch-making machine.

Quality Control: Ensuring Consistency in Production

Maintaining high quality throughout the production process is essential. Regularly check the finished product for seal strength, dimensions, appearance, zipper functionality, and overall sealing performance. Consistent inspections help ensure that your custom stand up pouch bags meet the highest standards.DINGLI PACK conducts a 100% three-time quality inspection to ensure that every product is flawless.

Conclusion: Your Trusted Partner in Packaging Solutions

At HUIZHOU DINGLI PACK CO., LTD., we specialize in creating custom stand up pouches tailored to your specifications. Our Custom Kraft Paper Ziplock Stand-Up Pouch with Window is eco-friendly, moisture-proof, and made from premium materials that are certified safe for food contact. With enhanced edge sealing and a transparent window, these pouches not only keep your products fresh but also attract customers.

With low minimum order quantities, we are here to support your business with sustainable packaging solutions that align with modern environmental goals. Partner with us today to elevate your product packaging and secure your packaging needs!

Post time: Nov-07-2024