When it comes to printing on kraft paper pouches, there are several challenges that businesses often face. Have you ever wondered why achieving high-quality prints on these eco-friendly, durable bags is so difficult? If you’re a business looking to create eye-catching, vibrant packaging for your products, understanding the limitations of kraft stand-up pouches is crucial.

Why Is Kraft Paper a Challenging Medium for Printing?

The rough texture of kraft paper, especially in kraft stand-up pouches, is one of its defining characteristics. While this gives the packaging an earthy, organic look, it also poses significant hurdles for achieving crisp, vibrant prints. The paper tends to shed fibers during the printing process, which can interfere with the application of ink, causing smudging, poor color reproduction, and blurry images.

Kraft paper is also highly absorbent, soaking up ink in a way that can cause dot gain—where the ink spreads beyond its intended boundaries. This leads to fuzzy edges and poor print clarity, particularly when fine details, small text, or intricate patterns are involved. This is a major challenge for businesses that want precision and sharpness in their branding.

Ink Absorption: How Does It Affect Print Quality?

One of the most frustrating aspects of printing on kraft paper pouches is how the material absorbs ink. Compared to other packaging materials, kraft paper behaves unpredictably. Its fibers pull in ink more aggressively, leading to uneven color application. This can result in: Inconsistent shades across the surface.

Difficulty achieving vibrant, bright colors, particularly on yellow kraft paper, which can further distort the final appearance.

Poor gradient transitions, where color shifts are abrupt rather than smooth.

Traditional printing methods like flexographic and gravure printing struggle to compensate for these irregularities. Many businesses are left with dull, lackluster results that don’t reflect the professional image they are trying to project.

Color Matching: The Challenge of Different Kraft Paper Batches

Unlike standardized materials like plastic, kraft stand-up pouches can vary greatly from one batch to another. Different brands of kraft paper often have slightly different tones—ranging from light to dark brown, and even yellow kraft paper. These variations make it challenging to achieve consistent color reproduction, especially when dealing with logos or packaging designs that rely on precise color matching.

For example, one batch of kraft paper may give your prints a warmer, brownish tint, while another batch may cool the tones, affecting the vibrancy of your design. This inconsistency is a significant drawback for brands that rely on visually cohesive packaging across multiple product lines.

Registration Issues: Keeping Everything Aligned

Printing on kraft paper pouch surfaces can also cause registration issues, where the different layers of ink used in the printing process don’t align correctly. This results in blurred or offset images, making the final product look unprofessional. The uneven surface of kraft paper makes it difficult to achieve accurate alignment, especially for intricate designs that rely on multiple colors or gradients.

This misalignment is particularly problematic for businesses that need detailed or complex designs to stand out. Brands that rely on high-resolution images and precise patterns may find that kraft paper simply can’t deliver the level of quality they need without significant adjustments.

Solutions for High-Quality Printing on Kraft Stand-Up Pouches

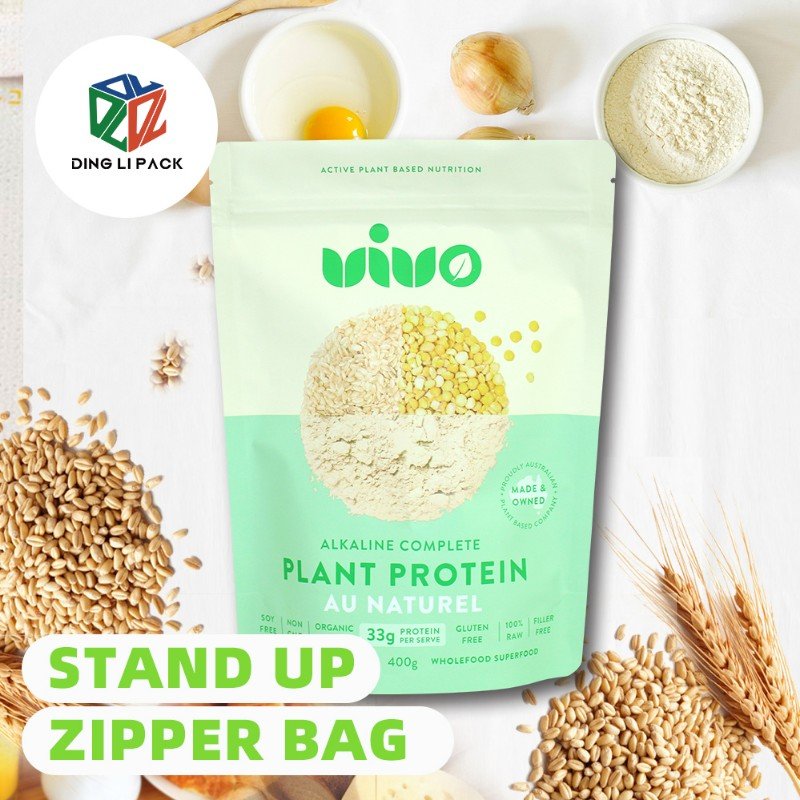

Despite the challenges, it’s not impossible to achieve beautiful, professional-looking prints on kraft stand-up pouches. Here are a few solutions that DINGLI PACK have developed:

Specialized Inks: Using water-based or UV inks designed specifically for porous materials like kraft paper can help minimize ink absorption and improve color vibrancy.

Digital Printing: Digital printing methods are becoming more advanced and offer better precision for challenging surfaces like kraft paper. They allow for sharper images and better color control.

Surface Treatment: Pre-treating the kraft paper surface can help reduce fiber shedding and create a smoother surface for ink application, reducing registration issues and improving print clarity.

By working closely with a packaging manufacturer experienced in printing on kraft paper, you can better navigate these challenges and achieve results that align with their brand’s image.

With cutting-edge digital printing methods and specialized inks, we guarantee consistent, reliable results that meet the highest industry standards. Whether you need kraft stand-up pouches for food products, cosmetics, or retail goods, we have the expertise to help your brand stand out.

FAQs on Kraft Paper Pouches

What types of products are these pouches suitable for?

● Answer: Kraft Stand-Up Pouches are suitable for various products, including food, beverages, coffee, snacks, spices, and dry goods.

What are Kraft Stand-Up Pouches?

● Answer: Kraft Stand-Up Pouches are self-standing bags made from Kraft paper. They are known for their durability and eco-friendly properties, suitable for packaging various products such as food, coffee, and snacks.

What are the advantages of these pouches?

● Answer: They offer excellent durability and protection, effectively blocking moisture and oxygen to maintain product freshness. Their self-standing design is convenient for display and use.

Can these pouches be customized?

●Answer: Yes, we offer customization services for printing, sizes, and sealing types to meet your specific needs.

Post time: Aug-27-2024