Iyo yekutanga gadziriro yemasaga ekurongedza mabhegi akakamurwa kuita matanho mana: kudhinda, laminating, kucheka, kugadzirwa kwemabhegi, ayo maviri maitiro ekumisa uye kugadzira mabhegi ndiwo akakosha maitiro anokanganisa kuita kwechigadzirwa chekupedzisira.

Compounding process

Dhizaini chigadzirwa chekurongedza maitiro, mukuwedzera kune chaiyo sarudzo yeakasiyana ma substrates, kusarudzwa kweanomisikidza anonamatira kunokosha zvakare, maererano nekushandiswa kwezvigadzirwa, kuumbwa, mamiriro ekugadzirisa, mamiriro emhando yemhando yekusarudza. Sarudza iyo inonamira isiriyo, zvisinei kuti yakakwana sei iyo composite yekugadzirisa tekinoroji, zvakare ichakonzera mhedzisiro yakaipa, pamwe nekumashure-kugadzirisa kuderedza simba, pasi pesimba remubatanidzwa, kuvuza, mabhegi akatyoka uye kumwe kutadza.

Sarudzo yemazuva ese kemikari inochinjika kurongedza nemanamira kuti utarise zvakasiyana-siyana zvezvinhu, kazhinji, seyakabatanidzwa inonamatira inofanirwa kusangana nemamiriro anotevera.:

Kwete-chepfu

Hapana zvidimbu zvinokuvadza zvinoonekwa mushure mekurongedza zvinwiwa.

Inoshanda kune zvinodiwa tembiricha zvekuchengetedza chikafu.

kunaka kwemamiriro ekunze kuramba, hapana kutsvuka uye kutsvuka, hapana chalking uye delamination.

kupikisa mafuta, zvinonaka, vhiniga uye doro.

Hapana kukukurwa kwekudhinda patani ingi, inotarisirwa kuve nehukama hwepamusoro hweinki.

Pamusoro pezvo, kuramba kukukurwa, zvirimo zvine huwandu hukuru hwezvinonhuwira, doro, mvura, shuga, mafuta acids, nezvimwewo, zvimiro zvavo zvinosiyana, zvinokwanisika kupinda mukati meiyo yemukati firimu remubatanidzwa muchikamu chekunamatira, zvichikonzera kukuvadzwa kwecorrosion, zvichikonzera delamination yebhegi rekurongedza, kukanganisa kukundikana. Nekuda kweizvozvo, iyo inonamira inofanirwa kuve nekugona kurwisa kukukurwa kwezvinhu zviri pamusoro, gara uchichengetedza zvakakwana adhesive peel simba.

Plastic film composite processing nzira dzakaoma composite nzira, yakanyorova composite nzira, extrusion composite nzira, inopisa melt composite nzira uye co-extrusion composite nzira uye dzimwe dzinoverengeka..

1, Dry musanganiswa

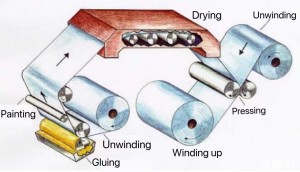

Dry lamination nzira ndiyo yakajairika nzira yepurasitiki kurongedza lamination. Pasi pemamwe mamiriro ekushisa, kushushikana uye kumhanya, yekutanga substrate inozadzwa zvakaenzana neyakagadzika ye solvent-based adhesive (chimwe-chikamu chinopisa chinonyungudusa adhesive kana maviri-chikamu reactive adhesive), mushure me laminating muchina kubikira chiteshi (yakakamurwa kuita nzvimbo nhatu: evaporation zone, kuomesa zone uye kubviswa kwezvinonhuhwirira nzvimbo, inoputika, inoputika uye inopfungaira hovha) uye ipapo mhepo inoputika mumhepo inopisa yekutsikisa uye yechipiri substrate (yepurasitiki firimu, pepa kana aluminium foil) yakasungirirwa mufirimu inoumbwa.

Dry lamination inogona laminate chero mhando yefirimu, uye inogona kutsiva kugona kugadzira yakakwirira-inoshanda yekurongedza zvinhu zvinoenderana nezvinodiwa nechinangwa zvinoenderana nezviri mukati. Naizvozvo, mukurongedza, kunyanya mune yemazuva ese kemikari packaging yakagadziriswa budiriro.

2,Wet compounding

Wet composite nzira iri composite substrate (plastiki firimu, aruminiyamu foil) akaturikidzana akaturikidzana anamira pamusoro pemvura, panyaya yokunamira haina kuoma, kuburikidza kumanikidzwa roller uye zvimwe zvinhu (bepa, cellophane) composite, uye ipapo akaomeswa pashure muchoto kupinda composite firimu.

Wet composite process iri nyore, ine shoma inonamira, yakaderera mutengo, yakakwira composite kunyatsoshanda, uye isingabatanidze yakasara solvent.

Wet composite laminating muchina uye kushanda musimboti rinoshandiswa uye yakaoma composite nzira zvakangofanana, musiyano ndiyo yekutanga substrate yakanamirwa guruu, kutanga nechechipiri substrate laminated composite, uye ipapo akaomeswa nechoto. Nyore, shoma inonamira dosage, kukurumidza kusanganisa, zvigadzirwa zvinosanganiswa hazvina zvakasara zvinonyungudutsa, kusvibiswa kumwe kune zvakatipoteredza.

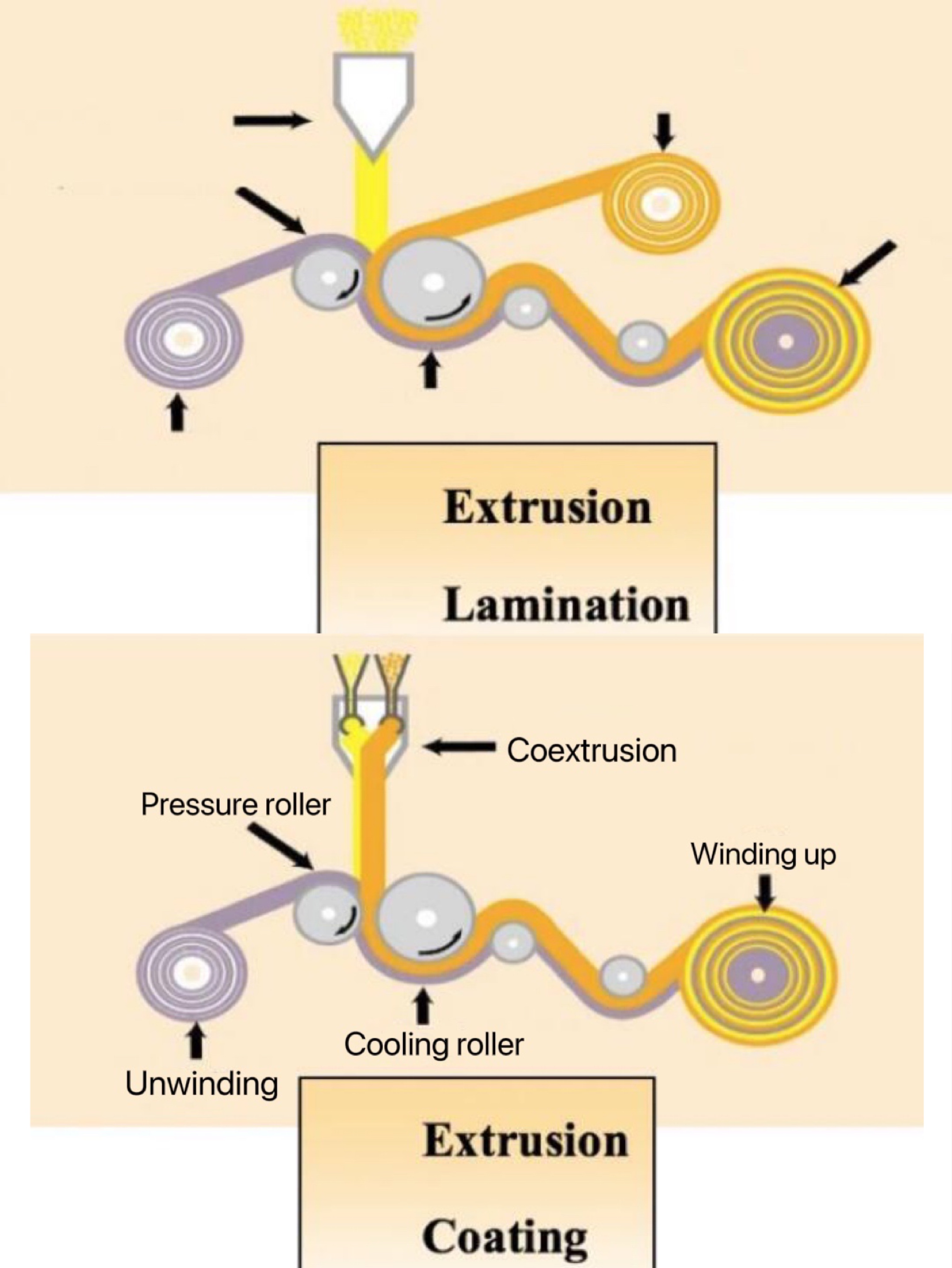

3, Extrusion musanganiswa

Kuwedzeredza kusanganisa ndiyo nzira yakajairika yekusanganisa maitiro, iko kushandiswa kwe thermoplastic resin seyakabikwa, resin inopisa uye inonyungudutswa muforoma, nemuromo unofa pachinzvimbo chekuporeswa kwepepa refirimu, pakarepo mushure mekusanganiswa neimwe mhando kana maviri mafirimu pamwe chete, uye yobva yatonhodzwa nekuporeswa. Multi-layer co-extrusion lamination yakasiyana-siyana yakasiyana-siyana yepurasitiki resin kuburikidza nekuwedzera kune extruder co-extrusion, kupinda mufa lamination mufirimu.

Composite zvinhu zvinowanzoitika kune zvemhando matambudziko uye mhinduro

Kubatanidza inzira inokosha mukugadzirwa uye kugadziriswa kwekuputira kushanduka, kukanganisa kwayo kwakajairika ndeku: kugadzirwa kwemhepo inoputika, kuderera kwekukurumidza kusanganiswa, zvigadzirwa zvakapedzwa zvakapedzwa uye zvakaputirwa micheto, zvigadzirwa zvinosanganiswa zvakatambanudzwa kana shrinkage, nezvimwewo.

1, Chiitiko chekuunyana

Mukuoma kwakaumbwa kukundikana kwechiitiko ichi kunotora chikamu chikuru chekukundikana kunobata zvakananga kunaka kwekugadzirwa kwechigadzirwa chakapedzwa.

Zvikonzero zvikuru zvekukundikana uku ndezvizvi zvinotevera.

Hunhu husina kunaka hwezvinhu zvakaumbwa kana kudhinda substrate pachayo, kutsauka muukobvu, mabhaisikopo akarembera akasununguka kumativi ese ari maviri uye akasimba kune imwe magumo nekuda kwekusagadzikana kwemhepo kunetsana. Kana iyo firimu vhoriyamu yakaparadzaniswa kubva kune elasticity yehombe, pamushini, iyo firimu kumusoro uye pasi uye kuruboshwe uye kurudyi kuiswa amplitude zvakare yakakura nekuti kana zvinhu zvinopinda pakati pedhiramu rinopisa uye rinopisa rekudhinda rollers, harigone kuenzana neanopisa ekudhinda rollers, saka haigone kudzvanywa sandara, zvichikonzera iyo yakapedzwa composite yakakwinya, mhedzisiro yechigadzirwa chakakwinyana. Kana iyo composite zvinhu iri PE kana CPP, kana ukobvu kutsauka kuchipfuura 10μm, zviri nyorewo kuunyana, panguva ino, tension yechinhu chinoumbwa inogona kuwedzerwa zvakakodzera, uye inopisa yekutsikirira roller inogona kuve yakatwasuka mamiriro e extrusion. Nekudaro, zvinofanirwa kucherechedzwa kuti kunetsana kunofanirwa kuve kwakakodzera, kushushikana kwakanyanya kuri nyore kugadzira iyo inoumbwa zvinhu kurebesa, zvichiita kuti muromo webhegi upinde mukati. Kana ukobvu kutsauka kwezvakasanganiswa zvinhu zvakakurisa, hazvigone kushandiswa, zvinofanirwa kugadziriswa.

2、Musanganiswa mavara machena

Somugumisiro murombo ingi kufukidzwa mwero chena makwapa: nokuti rinoumbwa chena ingi, apo ingi absorption volatilization asi kwete volatilization kunokonzerwa chena makwapa, iripo kuvandudza nokuomesa nzira; kana pachine makwapa machena, mhinduro yakajairika ndeyekuvandudza inki chena inovhara, sekutarisa kunaka kweinki chena, nekuti kukuya kwakanaka kweiyo inki kufukidzwa mwero yakasimba.

Adhesive pachinzvimbo chemavara machena anogadzirwa zvisina kuenzana: muinki yakavharwa neglue, nekuda kwekupinda muinki inotora chinonyungudutsa, kushushikana kwepasi uye kudiki pane substrate, kuenzana hakuna kunaka seyakajeka firimu rakaputirwa neglue, glue depressions uye aruminiyamu-plated pamusoro kana aluminium foil haisi yepedyo kuenderana, ichiratidza chiedza kuburikidza nechikamu chinopenya, chinoratidza chiedza kuburikidza nechikamu. yemavara machena. Mhinduro yacho inogona kushandiswa kupfavisa kupfekedza neyunifomu rubber roller, kana kuwedzera huwandu hwekutsiviwa.

3、Compound bubble

Composite bubbles inogadzirwa mumamiriro anotevera uye nzira dzinoenderana.

Compound bubbles mune chiitiko

1. firimu rakashata, rinofanira kuvandudza kusungirirwa kwekunamatira uye huwandu hwekutsiviwa, MST, KPT pamusoro haisi nyore kunyorova, nyore kugadzira mabhubhu, kunyanya munguva yechando. Mhepo inotubuka painki,anogonashandisa nzira yekuwedzera huwandu hwekunamatira kubvisa.

2,Iyo inki yepamusoro bump uye bubble, inofanira kusanganiswa firimu rinobatanidza tembiricha uye kusanganisa kumanikidza kuwedzera.

3, Kuwanda kwekuwedzera glue pamusoro peinki kwakaderera, kunofanira kuwedzera kusanganisa roller pressure paste time uye kushandiswa kwema rollers akatsetseka, firimu preheating zvakakwana kuderedza kukurumidza kusanganiswa, sarudza yakanaka wetting glue uye sarudzo yakarurama yeinki.

4. The additives (lubricant, antistatic agent) mufirimu inopindwa neglue, saka iwe unofanira kusarudza glue nehupamhi hwema molecular uremu uye kukurumidza kuporesa, kuwedzera kusanganiswa kweglue, kusimudza kupisa kwevheni kuti iomese glue, uye usashandise firimu nemwedzi inopfuura 3 yekuisa nguva, nokuti kurapwa kwekorona kwakarasika.

5,Tembiricha munguva yechando yakadzikira, iyo yakabatana kune firimu neingi kutamiswa, reset alignment mhedzisiro haina kunaka, saka nzvimbo yekuvhiya inochengetedza imwe tembiricha.

6,Iyo tembiricha yekuomesa yakakwira zvakanyanya, kuputika kweadhesive kana kuputika kweganda repamusoro kunoitika, uye mukati hauna kuoma, saka tembiricha yekuomesa yekunamatira inofanira kugadziridzwa.

7. Mhepo inopindirana pakati pefirimu ye-composite rollers, tembiricha ye-composite rollers inofanira kuwedzerwa uye kona inosanganiswa inofanira kusvibiswa (firimu yakaoma uye iri nyore kubudisa mabhubhu kana yakaoma).

8,Nekuda kweiyo yakakwira firimu chipingamupinyi, iyo CO2 gasi inogadzirwa neanonamira kurapa, yakasara mumubatanidzwa firimu, isina kudhindwa pabubble, inofanirwa kuvandudza huwandu hweanorapa agent, kuitira kuti adhesive kurapa mukuoma.

9. Iyo glycolic acid murubha inogadzirisa zvakanaka kune inki filler, rubber inonyungudutsa inki, uye pane mabhubhu chete painki, iyo inofanira kudzivisa kupinda kwemvura murubha uye kuvandudza kupisa kwekuoma kwerabha kuderedza kuparara kweinki.

4, Simba risina kusvuura

Simba rePeel harina kunaka, rinokonzerwa nekusakwana kupora, kana kuwanda kweglue kushoma, kana inki inoshandiswa uye inonamira haienderane nemamiriro ezvinhu, kunyangwe kupora kwapera, asi pakati pezvikamu zviviri zvemusanganiswa firimu nekuda kwekushaikwa kwehurefu kwakaderedza kuderedzwa kwesimba.

Huwandu hwejekiseni hweglue hwakanyanya kudiki, chiyero chekunamira chakaderedzwa, glue rinodzikira mukuchengetedza, mvura nedoro zvinosanganiswa muglue, vabatsiri mufirimu vanodzikiswa, kuomesa kana maturation maitiro haapo, nezvimwewo, izvo zvinotungamira kune yekupedzisira inoumbwa peel simba rekudzora zvinhu.

Nyatsoteerera kuchengetwa kwakakodzera kweglue, iyo yakareba haipfuuri gore 1 (tin inogona kuvharwa); kudzivirira zvinhu zvekune dzimwe nyika kupinda glue, kunyanya mvura, doro, nezvimwewo, izvo zvinogona kukonzera kukundikana kweglue. Firimu yakakodzera kuvandudza huwandu hweglue coating; kunatsiridza tembiricha yekuomesa mhepo vhoriyamu, kuderedza kumhanya kwekubatanidza. Kurapa kwechipiri kwefirimu pamusoro pekuvandudza kushushikana kwepamusoro; kuderedza kushandiswa kwezvinowedzera mufirimu yekubatanidza pamusoro. Idzi nzira dzese dzinogona kutibatsira kuvandudza dambudziko rekushaya simba peel recomposite.

5. Kupisa chisimbiso chakaipa

Compound bhegi kupisa chisimbiso kuita kwakashata uye zvikonzero zvayo ndiwo anotevera mamiriro.

Kupisa kwekuvhara simba kune urombo. Zvikonzero zvikuru zvechiitiko hachina kupora zvachose kana kupisa kwekuvhara tembiricha yakanyanya kuderera. Gadzirisa maitiro ekurapa kana zvakakodzera kuwedzera kupisa kwebanga rekuvhara kunogona kugadzirisa dambudziko.

Kupisa chisimbiso chivharo delamination uye refractive index. Chikonzero chikuru chechiitiko ichi ndechekubatana hakusi kurapwa. Gadzirisa nguva yekurapa kana gadzirisa iyo inorapa ejenti yemukati inogona kugadzirisa dambudziko iri.

Kushama kuvhurika / kushomeka kuvhurika kwemukati firimu remukati. Honzeri yechiitiko ichi idiki yekuvhura mumiriri, zvichiita kuti pave nezvakawandisa (modifier) uye inonamira kana girizi firimu pamusoro. Dambudziko iri rinogona kuvandudzwa nekuwedzera huwandu hwekuvhura mumiriri, kugadzirisa huwandu hwekugadzirisa, uye kudzivirira kusvibiswa kwechipiri pane firimu pamusoro.

Magumo

Tinokutendai nekuverenga kwenyu, tinovimba kuti isu tine mukana wekuve vabatsiri vako.

Kana uine chero mubvunzo waunoda kubvunza, ndapota inzwa wakasununguka kutizivisa uye kutibata nesu.

Contact:

Chikero chetsamba yemumhepo :fannie@toppackhk.com

Whatsapp : 0086 134 10678885

Nguva yekutumira: Kubvumbi-01-2022